-spilly's D44 sas

#1

-spilly's D44 sas

hey guys. finally getting around to starting my official sas thread after paying a visit to my buddys tire shop and discovering just how bad of shape my front end is really in. so far the list of broken parts is almost comical:

driver side - upper ball joint, lower ball joint, cv shaft, upper control arm bushings, tie rod end, upper shock bushing, and i replaced my hub assembly about 5 months ago

passenger side - upper and lower ball joints, torn cv shaft boot, upper control arm bushings, tie rod end and upper shock bushing

basically destroyed $500 worth of tires

only got pics of the worn tires after we flipped them, the wear was on the inside before im just trying to make them last untill i can sas

BUT, ive been collecting parts for my sas for a fair bit of time now and have almost everything i will need to complete the sas

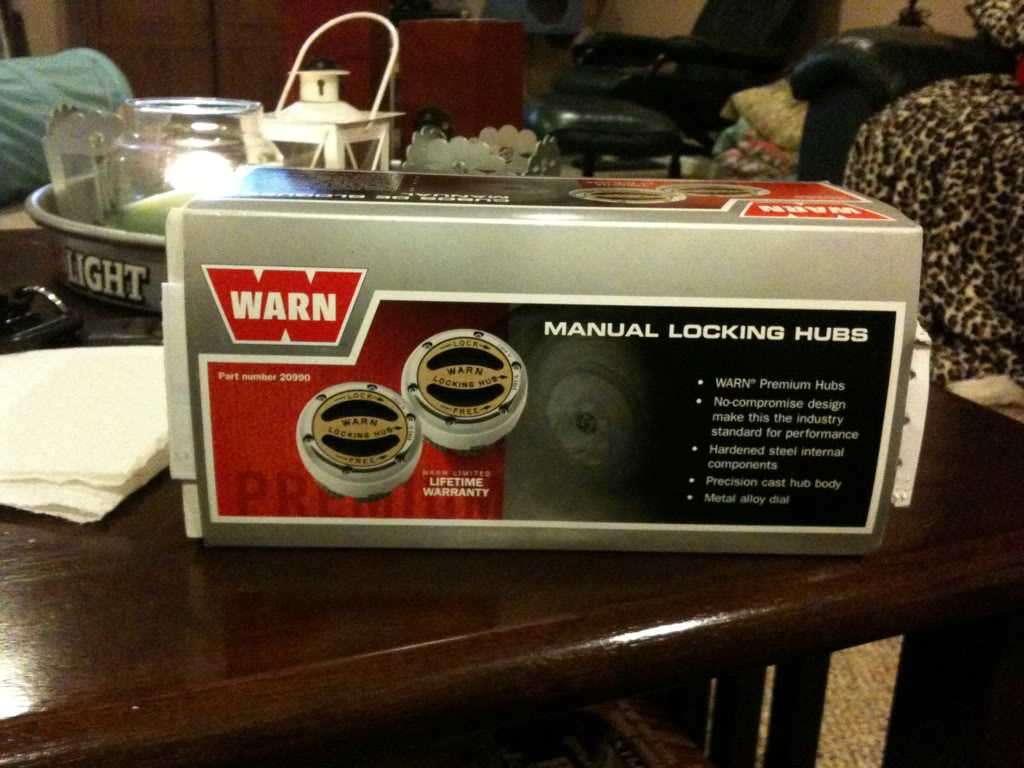

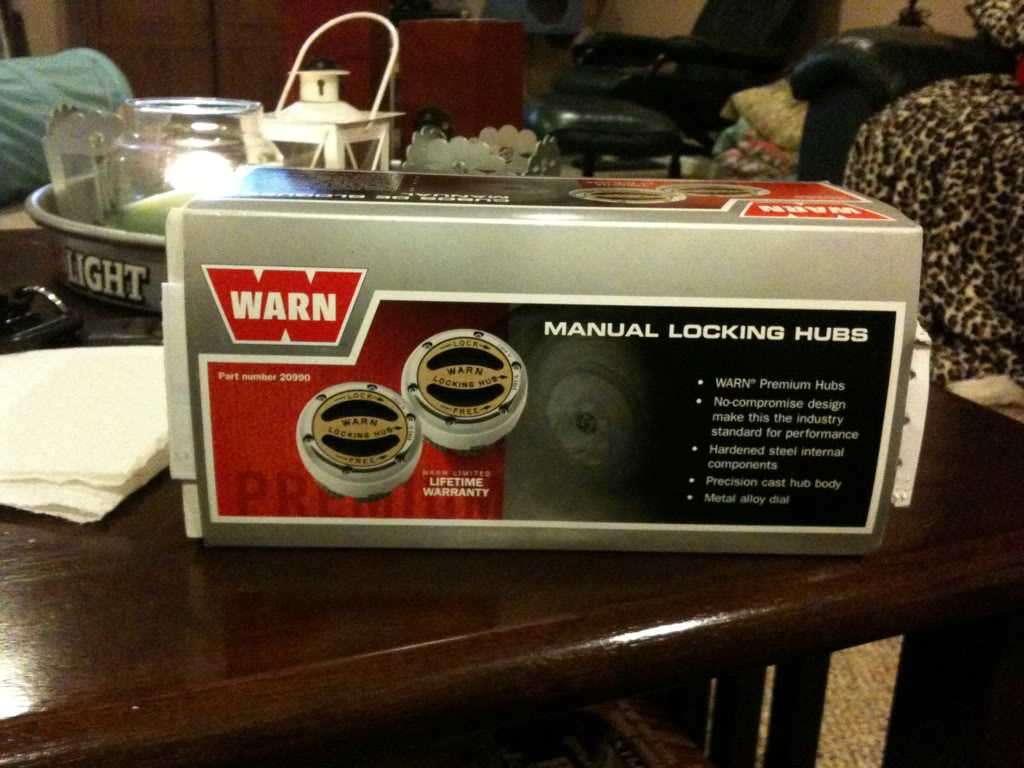

my axle is from a 1988 or 89 grand wagoneer. unfortunately i dont have any recent pictures of it but its been striped down cleaned, painted and fitted with a set of milled and drilled chevy flat top knuckles. knuckles have been made to take ES150 tie rod ends and i will be running high steer/crossover steer untill i decide to do otherwise. ive installed warn premium hubs and am running al spicer joints up front. this will be a leaf spring sas. i have a set of custom made mcallister leaf springs that are built to the same specs as the trail gear leafs that trepaul86 is running. i have my 4runner steering box that i got from the pick-a-part. the 4 runner was demolished from the back seat and back but the front was mint so hopefully the box is not in to bad of shape. got a new pitman arm with es150 taper put in and ive already received my fittings from psc motor sports (took two months to get to me lol) and to solve my destroyed tire problem.... i got a practically brand new set of 315/75 r16 bfg KM2's to put on. they still have those rubber nipple things on them. got them for $900 with eagle alloy rims but they are fullsize chev/dodge bolt patern (8X6.5 i think) i already have shock hoops and have cut the frame plate for the steering box all that i have left to do is finish buying some dom tubing to finish my steering and fab my crossmember and shackles, some brake lines and other odds and ends. some pictures bellow to keep the masses entertained. hopefully i will be able to realy get my stuf together and make this happen sooner than later.

(yota steering box)

(cutting frame plates)

(power steering fittings)

(stripped the axle)

(sand blasted and painted)

(knuckles and high steer arm fresh from the machine shop)

(new hubs)

(front mcallister leafs)

(answer to my tire problems)

so thats all for now but i will keep u to date with my progress and as things get closer to sas time there will be much more pictures and excitement to come!

driver side - upper ball joint, lower ball joint, cv shaft, upper control arm bushings, tie rod end, upper shock bushing, and i replaced my hub assembly about 5 months ago

passenger side - upper and lower ball joints, torn cv shaft boot, upper control arm bushings, tie rod end and upper shock bushing

basically destroyed $500 worth of tires

only got pics of the worn tires after we flipped them, the wear was on the inside before im just trying to make them last untill i can sas

BUT, ive been collecting parts for my sas for a fair bit of time now and have almost everything i will need to complete the sas

my axle is from a 1988 or 89 grand wagoneer. unfortunately i dont have any recent pictures of it but its been striped down cleaned, painted and fitted with a set of milled and drilled chevy flat top knuckles. knuckles have been made to take ES150 tie rod ends and i will be running high steer/crossover steer untill i decide to do otherwise. ive installed warn premium hubs and am running al spicer joints up front. this will be a leaf spring sas. i have a set of custom made mcallister leaf springs that are built to the same specs as the trail gear leafs that trepaul86 is running. i have my 4runner steering box that i got from the pick-a-part. the 4 runner was demolished from the back seat and back but the front was mint so hopefully the box is not in to bad of shape. got a new pitman arm with es150 taper put in and ive already received my fittings from psc motor sports (took two months to get to me lol) and to solve my destroyed tire problem.... i got a practically brand new set of 315/75 r16 bfg KM2's to put on. they still have those rubber nipple things on them. got them for $900 with eagle alloy rims but they are fullsize chev/dodge bolt patern (8X6.5 i think) i already have shock hoops and have cut the frame plate for the steering box all that i have left to do is finish buying some dom tubing to finish my steering and fab my crossmember and shackles, some brake lines and other odds and ends. some pictures bellow to keep the masses entertained. hopefully i will be able to realy get my stuf together and make this happen sooner than later.

(yota steering box)

(cutting frame plates)

(power steering fittings)

(stripped the axle)

(sand blasted and painted)

(knuckles and high steer arm fresh from the machine shop)

(new hubs)

(front mcallister leafs)

(answer to my tire problems)

so thats all for now but i will keep u to date with my progress and as things get closer to sas time there will be much more pictures and excitement to come!

#5

gonna be as soon as i can get it into my buddys shop. hes got a bronco that hes putting a big block in and 3link and a bunch of other stuff so prob gonna go under the knife in about 2 months (if the truck makes it that long in its current condition) maybe sooner. im picking up some new wheels so i can mount the km2's and move the axle around a little easier. basically the last major expense that i see is going to be steering. im going to have a local guy make me a custom intermediate shaft so its going to be splined in case i get a V.I. picking up some dom hopefully next week and i need 2 more tie rod ends then im gonna start by mounting the toyota box early so its one less thing to do on sas day. not gona leave the box on when driving but the frame will at least be sleeved and plated so that should save some time. im going to sleeve the frame for the shackles to help keep the truck a little lower too. one thing id like to know is who makes adapters for the rear to mach the 6x5.5 bolt pattern? every 4wd shop i asked around here says im crazy for thinking such a thing exists!

#7

Try this guy: http://lugnutking.ca/

It's not much of a site, but if you contact him he may have something (and he's actually in Canada!) I met him at a swap meet a year or two back and he had boxes and boxes of adapters.

It's not much of a site, but if you contact him he may have something (and he's actually in Canada!) I met him at a swap meet a year or two back and he had boxes and boxes of adapters.

#9

thanks adam. i didnt see any adapters on his websire but ill be sure to contact him and see if he can help me out.

as for any new news, i got some new rims on order and the metal shop is bringing in some dom tubing for me also. hopefully by monday i will have the rims mounted and if im lucky i will be able to start working on mounting the steering box. im going to have a friend cut some new threads into the dom for my tie rod ends and then i can assemle the whole axle. maybe if i have time i will have the spring hanger made my the end of next weekend but we will see. i keep posted tho.

as for any new news, i got some new rims on order and the metal shop is bringing in some dom tubing for me also. hopefully by monday i will have the rims mounted and if im lucky i will be able to start working on mounting the steering box. im going to have a friend cut some new threads into the dom for my tie rod ends and then i can assemle the whole axle. maybe if i have time i will have the spring hanger made my the end of next weekend but we will see. i keep posted tho.

#10

#11

Follow my thread. A lot of info and troubleshooting took place there

Here's my adapters:

http://www.tulipcitywheels.com/tcwst..._detail&p=1356

Here's my adapters:

http://www.tulipcitywheels.com/tcwst..._detail&p=1356

#12

thanks trevor. ive read your build thread post for post a couple times as well as every other sas thread on r-f and other sites and everything ive seen has all been super informative. i know im going to have many of my own questions and set backs but reading all the different threads has given me a great idea on how to tackle most any issue. the guy who is helping me do the sas has done well over a dozen toyota sas's and his work truck is a chevy 1500 with a d44 sas on 38's so i feel like im in good hands for this. he is confident that after day two it will be sitting on its own weight and and by the end of day four he is suggesting that we should have all the bugs worked out. i know he knows his stuff im just hoping hes not being overly optimistic but assuming hes got his time line rite it should be a fairly quick process. (hopefully)

#13

Wirelessly posted (Droid X)

I don't mean to **** on your parade, but it wont happen in 4 days having all the bugs worked out. Trust me, I said the same thing. Mine turned into a 2 week project which ran more into 3 weeks by the time I got it all under control. And I had a buddy who builds link setups all the time helping me at his shop.

Just be prepared for a week to two weeks of bugs to work out. I'm not doubting his skills or anything, but everything on a ranger sas is pieces. No kit that's proven to work outta the box ya know?

Still, can't wait to see this build!

I don't mean to **** on your parade, but it wont happen in 4 days having all the bugs worked out. Trust me, I said the same thing. Mine turned into a 2 week project which ran more into 3 weeks by the time I got it all under control. And I had a buddy who builds link setups all the time helping me at his shop.

Just be prepared for a week to two weeks of bugs to work out. I'm not doubting his skills or anything, but everything on a ranger sas is pieces. No kit that's proven to work outta the box ya know?

Still, can't wait to see this build!

#14

I figured the the guy was being rather optimistic with his time line but who knows. It's nice to think he's rite but I do expect it to take a little longer lol. I got the girlfriends jeep to drive during the swap so I won't be totally out of a ride if it takes a few weeks or something. I'm just excites toget things moving!

#16

#18

well today i was suposed to get my new rims but the shop i was getting them through **** the bed and forgot to bring them in for today so i should be getting them sometime in the next day or two. however i did get my tie rod ends and the dom tubing for my steering. picked up one one ton tie rod end from the auto store and got the dom and the other tie rod end for a sandwich and a beer lol. tomorrow im gonna stay late after work and cut the dom to length and drill and tap it. little by little the last few things are being ordered just a matter of time now!

#20

No sir. In order to make it 100% street legal (at least in B.C.) you aren't aloud to weld anything in your steering. Steering dampeners have to be clamped on you can't weld on tabs. That's why I bought the long tie rod end with the eye in it because I am able to attach a steering dampener to that. After I cut the Dom to required length I'm gonna drill it out to size them run a left hand 7/8"-19tpi tap through the end and put a jam nutt on it. Only way it will pass any kind of inspection if I were to ever get one

#21

so i cut and tapped the dom or steering.i went this route that way there is no need to weld in inserts and it will pass any vehicle inspection.

this is my buddys sas'd chev, the guy who owns the shop. i am doing the same thing with the steering that hes done where he hooked up his steering dampener to the tie rod end. im doing the same thing with my truck. he has some laser cut tabs that we are welding to the axle to mount the dampener to.

as far as my rims go im not gonna see them for about two weeks now. they kinda screwed me but its not a major set back, just annoying. nothing new otherwise but hopefully by the weekend i will have more progress. i might have time to start getting my frame plates cut and the sleeves welded up.

this is my buddys sas'd chev, the guy who owns the shop. i am doing the same thing with the steering that hes done where he hooked up his steering dampener to the tie rod end. im doing the same thing with my truck. he has some laser cut tabs that we are welding to the axle to mount the dampener to.

as far as my rims go im not gonna see them for about two weeks now. they kinda screwed me but its not a major set back, just annoying. nothing new otherwise but hopefully by the weekend i will have more progress. i might have time to start getting my frame plates cut and the sleeves welded up.

#22

so some new progress. got my crossover steer done and picked up my new rims today. gonna fully assemble my axle before the end of the weekend and mount my tires as well.

on monday im having my brakelines made up by a local shop, however should i cut back the brake lines back and put a diferent fitting on the line or just use the existing fitting and line length that is on the truck already? if im just going to re-use the existing fitting anyone know what size it is?

also this might be happening much sooner than i had anticipated. my truck is in real bad shape and its becoming dangerous to drive. im more than likely gonna drop the front diff and just cut my cv shaft stubs off to keep the wheels on the truck, seeing as how they are already broken and making allot of vidration and noise. but i might pull it off the road in a few weeks if i cant make it last till i can do the sas. either way im gonna be emptying the wallet now and just grabbing all the rest of the stuff i need so if i do ned to start cutting into it soooner than i expecting im gonna be good to go.

on monday im having my brakelines made up by a local shop, however should i cut back the brake lines back and put a diferent fitting on the line or just use the existing fitting and line length that is on the truck already? if im just going to re-use the existing fitting anyone know what size it is?

also this might be happening much sooner than i had anticipated. my truck is in real bad shape and its becoming dangerous to drive. im more than likely gonna drop the front diff and just cut my cv shaft stubs off to keep the wheels on the truck, seeing as how they are already broken and making allot of vidration and noise. but i might pull it off the road in a few weeks if i cant make it last till i can do the sas. either way im gonna be emptying the wallet now and just grabbing all the rest of the stuff i need so if i do ned to start cutting into it soooner than i expecting im gonna be good to go.

#24

just out of curiosity, how much did they cost you? ive shopped around and cant find them for less than $100 (in a 16x8) each in canada but was hoping to find them in the states for less but havent looked into it yet. if i can find them cheaper id just go across the border and pick them up

#25

Well seeing as how photobucket has finally started working for me again I can update with some pics. The axle is now totally assembled again and wheels are mounted. Picked up my brake lines the other day and earlier this afternoon I picked up my intermediat shaft set up. I was going to go the route of the e250 shaft but no one around here would even look at what needs to be done after I had explained the situation so I just went the easy but costly way of all borgeson intermediate shaft and joints. The joints mate up to the ranger shaft the same way hooking up the E250 shaft does and the other joint splints onto the Toyota box and the intermediat shaft is splined so it's bot d.o.t approved and easy to install. All I have to do is cut it to length and it's done. I'm still going to have to make a support for the shaft but I can get the steel an pillow block from work for free.

Looks like may long weekend might be when I start now. All I have left to do is build my hanger and order some wheel adaptors and some shox and a few other odds and ends. But as of now the start date is not set in stone.

Looks like may long weekend might be when I start now. All I have left to do is build my hanger and order some wheel adaptors and some shox and a few other odds and ends. But as of now the start date is not set in stone.