Another 3.0 misfire

#1

Another 3.0 misfire

Hello I recently got a truck for college cause I was told it was reliable itís a 2006 Ford ranger 3.0 v6 and itís been working amazing up until now. I bought a scanner because when I would drive the check engine light would flash and Iíd go to press the gas and nothing would occur no revs no moving nothing. Then out of nowhere it would go again. I got the codes p0300, p0304, p0305, p0306, p0174, and p0171.I changed the oxygen sensor on the driver side up top the annoying one and I changed the spark plugs and I noticed that they were all miss matched different brands. It ran better but still misfired. I bought some junkyard plugs and it ran worse so I figured mine were good. I checked for spark on all of em. So I figured I have a problem regarding fuel or vacuum leak. Changed the fuel filter and as I removed the intake manifold hoping the gaskets was fucked I pulled the fuel injectors and cleaned them all. I put everything back together. Took it for a drive and and the idle is still rough at idle. When I put it in R or D I have to keep it above a certain RPM to keep it alive or it will want to kill itself. Horrible shaking I still havenít gotten a code for misfires but I want to think I got the misfires taken care of. Any help? I know they have a problem with the heads Iím hoping it doesnít lead to it. I will also attach a video of my live data from the OBD I donít really understand how to read everything.

#2

Welcome to the forum

Unfortunately you may have the "recessed exhaust valve seat" issue that effected 2004-2006 Rangers with 3.0l engine

TSB here on that: https://www.therangerstation.com/for...n-tsb-05-26-3/

You should do a compression test

All spark plugs removed first

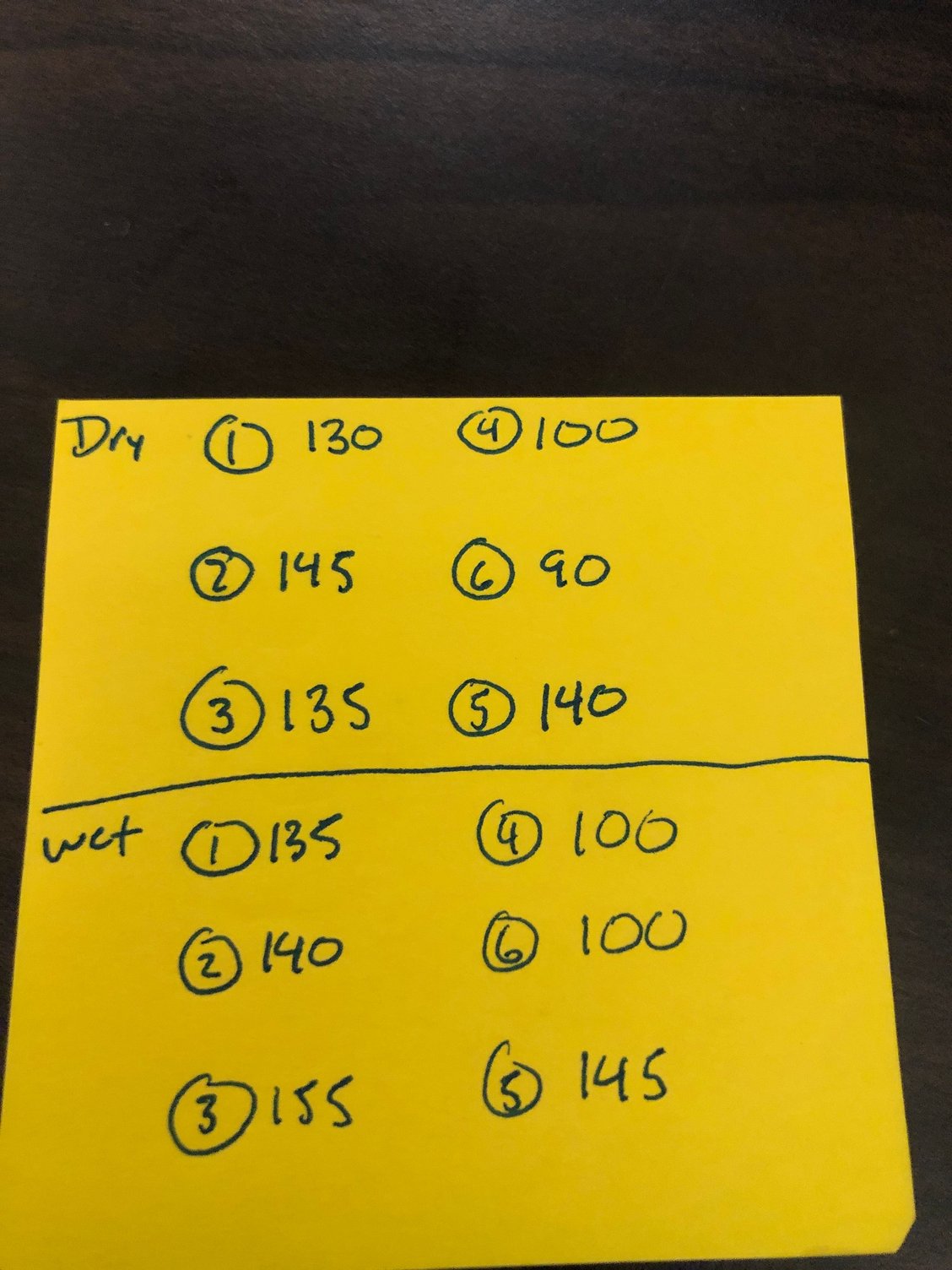

Then test each cylinder dry and write down results

Then add a teaspoon of oil to each cylinder, a WET test and test compression again

It will always go up, but if it doesn't go up to 165psi then there is a valve issue in that cylinder

Just use a straw dipped in a bottle of oil to add oil via spark plug hole

You can try a new Coil Pack, as these can crack and cause misfires

The Lean Codes are because of the misfires not the cause of the misfires

O2 sensors read Oxygen levels in exhaust, not fuel level

When a cylinder misfires no Oxygen is burned up so it all goes into the exhaust manifold and O2 sees that as "lean burn" too much oxygen

So you need to solve the misfires first and Lean codes may go away

FYI, the flashing CEL means misfires are occurring at that time so "back off the gas pedal" or engine damage my occur

Unfortunately you may have the "recessed exhaust valve seat" issue that effected 2004-2006 Rangers with 3.0l engine

TSB here on that: https://www.therangerstation.com/for...n-tsb-05-26-3/

You should do a compression test

All spark plugs removed first

Then test each cylinder dry and write down results

Then add a teaspoon of oil to each cylinder, a WET test and test compression again

It will always go up, but if it doesn't go up to 165psi then there is a valve issue in that cylinder

Just use a straw dipped in a bottle of oil to add oil via spark plug hole

You can try a new Coil Pack, as these can crack and cause misfires

The Lean Codes are because of the misfires not the cause of the misfires

O2 sensors read Oxygen levels in exhaust, not fuel level

When a cylinder misfires no Oxygen is burned up so it all goes into the exhaust manifold and O2 sees that as "lean burn" too much oxygen

So you need to solve the misfires first and Lean codes may go away

FYI, the flashing CEL means misfires are occurring at that time so "back off the gas pedal" or engine damage my occur

#3

#4

Need compression test first, then you won't waste time or money on non-fixes, if its a valve seat issue, compression is black and white, no maybes

The flashing CEL will come and go, and only come when its a bad misfire, usually only when accelerating

But you should still feel if its misfiring at idle or under load, a vibration, random misfires are the worst, which is kinda of what you have, p0300, p0304, p0305, p0306

Cylinders 4, 5 and 6 are on the drivers side of engine(bank 2) so could be a vacuum leak in lower intake on that side, but could be that this one head got the bad exhaust valve seats

The flashing CEL will come and go, and only come when its a bad misfire, usually only when accelerating

But you should still feel if its misfiring at idle or under load, a vibration, random misfires are the worst, which is kinda of what you have, p0300, p0304, p0305, p0306

Cylinders 4, 5 and 6 are on the drivers side of engine(bank 2) so could be a vacuum leak in lower intake on that side, but could be that this one head got the bad exhaust valve seats

#6

4 and 6, of course, have valve issues, usually exhaust valve and seat, but could be a blown head gasket on drivers side

Assuming you are using Ford numbering, drivers side is front 4 5 6

Coil pack is different

If 4 and 5 are the low cylinders then could be a blown head gasket between those 2 cylinders

Assuming you are using Ford numbering, drivers side is front 4 5 6

Coil pack is different

If 4 and 5 are the low cylinders then could be a blown head gasket between those 2 cylinders

#7

So I was told that the cylinders were 4,6,5 starting with cylinder 4 at the very front and 6 in the middle. I think it would be a valve issue because the spark plugs on the center and rear look really dark compared to the rest. They were brand new and I drove around to see if that would fix the misfire issue. This was before the compression fee days backs. But I ordered new heads with valves and springs. It came in a pair, might as well replace both sides correct? Is there anything I should watch for? Thanks

#8

Well you were given incorrect information on Ford cylinder numbering, it doesn't matter except when two adjacent cylinders both have lower compression then could be head gasket issue between the two

Seen here: https://www.fixya.com/uploads/images/852650d.jpg

Seen here: https://www.fixya.com/uploads/images/852650d.jpg

The following users liked this post:

B.aguilar (10-13-2020)

#9

#10

#12

#14

Because its a 2006 3.0l Ranger and you have what looks to be a valve issue in one head its actually best to replace both because it means that one head had defective valve seats installed and odds are the other head got the same batch of seats when it was assembled, not 100% for sure, but I would say at least 90%

From 2003 to 2005 Fords 3.0l engine assembly plant had a bad batch of exhaust valve seats delivered, these engines were put into 2004-2006 Rangers, there was, and is, no pre-test for this, you only know when they fail

And its not 100% of these engines that have the issue, the bad seats went into the heads and then heads are put on shelves, then picked later to be put on engines so there is no serial number trail either

So its a roll of the dice that you other head also has bad valve seats

A machine shop can pressure test head, which is not proof it is good but at least would show if its bad at this time

From 2003 to 2005 Fords 3.0l engine assembly plant had a bad batch of exhaust valve seats delivered, these engines were put into 2004-2006 Rangers, there was, and is, no pre-test for this, you only know when they fail

And its not 100% of these engines that have the issue, the bad seats went into the heads and then heads are put on shelves, then picked later to be put on engines so there is no serial number trail either

So its a roll of the dice that you other head also has bad valve seats

A machine shop can pressure test head, which is not proof it is good but at least would show if its bad at this time

#15

Yeah I figured, I bought the other head replace both, itís better to be safe than sorry and Iíd rather do it once and do it right then having to take it apart again. Thank you. Any tips or advice for doing this or is it straight forward? Also do you know the torque specs for the head bolts

#16

Head bolts are TTY, so can't be reused, they will break

1999 and up use

1. Tighten each bolt to 38ft/lb

2. Loosen each 1 full turn

3. Tighten each 24ft/lb

4. Turn each 90deg

5. Turn each another 90deg

Anytime you see "turn XX Degrees" it means its a TTY bolt so can't be reused, these types of bolts are made to be stretched, but once they are stretched they can't stretch again, so if loosened they are done

These TTYs actually hold better but are used by engine makers because machines build the engines now and tighten all the bolts by torque specs means machine would have to be calibrated a few times a week if not daily, but 90deg is EASY for a machine to do

Any torque under 40ft/lb is not critical, it can be off 5, even 10ft/lb without an issue

1999 and up use

1. Tighten each bolt to 38ft/lb

2. Loosen each 1 full turn

3. Tighten each 24ft/lb

4. Turn each 90deg

5. Turn each another 90deg

Anytime you see "turn XX Degrees" it means its a TTY bolt so can't be reused, these types of bolts are made to be stretched, but once they are stretched they can't stretch again, so if loosened they are done

These TTYs actually hold better but are used by engine makers because machines build the engines now and tighten all the bolts by torque specs means machine would have to be calibrated a few times a week if not daily, but 90deg is EASY for a machine to do

Any torque under 40ft/lb is not critical, it can be off 5, even 10ft/lb without an issue

Last edited by RonD; 10-14-2020 at 08:58 PM.

#17

Yeah I figured I read something about needing new bolts, I have them thank you. Also how do I clean the surface? I know I can use a scraper blade but Iíve seen people use wire wheels and even some abrasive that looks like scotch brite. Can I use break cleaner on it? And even on the pistons, Iíd like to clean the pistons heads while Iím at.

#18

Sure you can rotate engine to put a piston at the top and wire brush it to get carbon off it

Scraper and scotchbrite are fine to use on head gasket surface

I would pull the water pump and then after the cleaning is all done, clean out the blocks water passages

I use a smaller hose that fits down the larger coolant passage holes in the block, then run tap water from hose thru it

Use a long screwdriver down the holes to loosen rusty debris stuck in the corners around the cylinders, you will feel it, lol, and you can't hurt anything the block and cylinder walls are very thick

Debris will wash out water pump holes so have a BIG pan or do it outside

And I would wait to drain the oil until AFTER you are done flushing and cleaning, then any debris or water will come out with the oil when it drains out

If you have already drained the oil then get a cheap quart of oil and pour it in around the valley washing any debris out and then down and out of the oil pan

Scraper and scotchbrite are fine to use on head gasket surface

I would pull the water pump and then after the cleaning is all done, clean out the blocks water passages

I use a smaller hose that fits down the larger coolant passage holes in the block, then run tap water from hose thru it

Use a long screwdriver down the holes to loosen rusty debris stuck in the corners around the cylinders, you will feel it, lol, and you can't hurt anything the block and cylinder walls are very thick

Debris will wash out water pump holes so have a BIG pan or do it outside

And I would wait to drain the oil until AFTER you are done flushing and cleaning, then any debris or water will come out with the oil when it drains out

If you have already drained the oil then get a cheap quart of oil and pour it in around the valley washing any debris out and then down and out of the oil pan

#19

#21

Same as any V6 head sequence, seen here: https://ww2-secure.justanswer.com/up...51328_head.gif

Best practice is to mark each bolts head after the 22-24ft.lb tightening, put mark pointing to center of engine on each bolt head, then follow the sequence and each bolts mark should now be 90deg from center(so pointed to front or back of engine depending on which head you are tightening)

Then repeat 90deg again and each bolts mark will now be pointed at exhaust manifold side of head

90deg is 1/4 turn on the bolt/torque wrench, so if tightening the passenger side head bolts, you put the torque wrench on the bolt with handle facing center of engine, then you rotate the bolt/handle so its at/facing the front of the engine, 1/4 turn

80 to 100degs is fine, close counts with this type of bolt tightening

Best practice is to mark each bolts head after the 22-24ft.lb tightening, put mark pointing to center of engine on each bolt head, then follow the sequence and each bolts mark should now be 90deg from center(so pointed to front or back of engine depending on which head you are tightening)

Then repeat 90deg again and each bolts mark will now be pointed at exhaust manifold side of head

90deg is 1/4 turn on the bolt/torque wrench, so if tightening the passenger side head bolts, you put the torque wrench on the bolt with handle facing center of engine, then you rotate the bolt/handle so its at/facing the front of the engine, 1/4 turn

80 to 100degs is fine, close counts with this type of bolt tightening

Last edited by RonD; 10-15-2020 at 02:04 PM.

#22

I think sheís fixed

I finished replacing the heads took it for a spin ran great!! Although I did get these two codes p0340 and p0174. Would it have to do with anything regarding the exhaust manifold? I managed to snap one stud on the driver side. And the bolt on the driver side below the one I snapped I couldnít get the bolt to line up, soo that one doesnít have any bolts. Would that be the problem? If so can I get these at Home Depot or can I take it to a muffler shop? And how much would either be cause the $70 for a set is a b**ch. I do hear an exhaust leak soo Iím sure it has to be that, I just want confirmation, it sounds like a Harley when I gas it or at idle and I can smell exhaust fumes.

#23

You should post definition with code because no one has them all memorized, lol

P0174 System too Lean (Bank 2)

Bank 2 is drivers side so yes, an exhaust manifold leak will suck in air not just leak exhaust so it would cause a false lean on that side

An exhaust shop can fix it, they do it daily, so know a few tricks, but not sure on the cost, they have replacement bolts

Because its a false lean that side will be running too rich so engine won't run well because of that, and will foul spark plugs on that side after awhile

P0340 Camshaft Position Sensor Circuit Malfunction

Did you plug the cam sensor back in?

It in the back top of engine, 2 wire connector in 2006

If you removed the tower it sits on it does need to be re-timed to the engine

P0174 System too Lean (Bank 2)

Bank 2 is drivers side so yes, an exhaust manifold leak will suck in air not just leak exhaust so it would cause a false lean on that side

An exhaust shop can fix it, they do it daily, so know a few tricks, but not sure on the cost, they have replacement bolts

Because its a false lean that side will be running too rich so engine won't run well because of that, and will foul spark plugs on that side after awhile

P0340 Camshaft Position Sensor Circuit Malfunction

Did you plug the cam sensor back in?

It in the back top of engine, 2 wire connector in 2006

If you removed the tower it sits on it does need to be re-timed to the engine

#25

didnít google it. I believe thatís the catalyst efficiency code. Bank 2 cat specifically. Doesnít necessarily mean the cat is bad, could be caused by malfunctioning downstream o2 sensor.