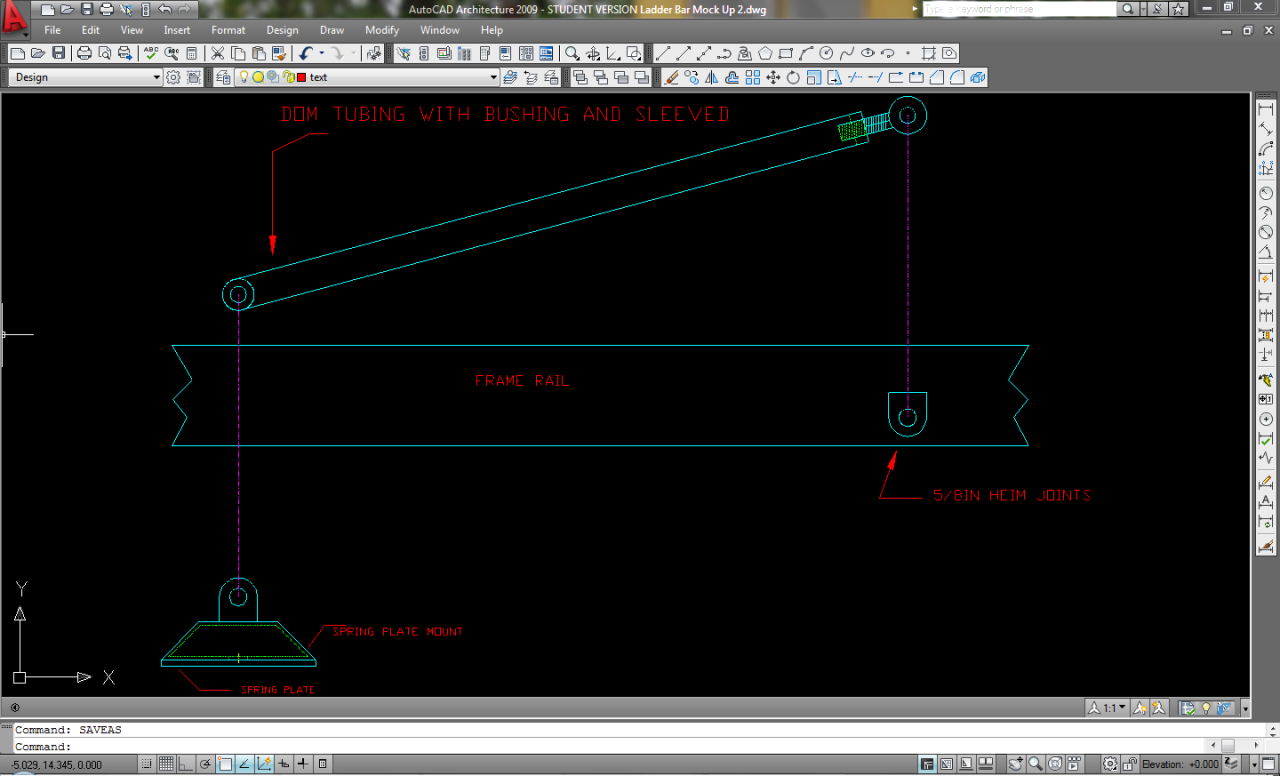

Ladder bar mock up

#1

Ladder bar mock up

What do you guys think? I already got the mounts made today... The triangular piece, picked up four 5/8in heim joints and found myself the 1.25 DOM round tubing and have it ready to cut...

Just seeing what you guys think? It'll either be welded to my expo spring plates I have in the garage, or they'll have tabs on them that will bolt on top of the plate under the the u-bolt nuts... Haven't decided that yet...

I decided to go with heim joints so I still have pivoting action when flexing, but this will keep the axle stationary in the y-axis, if you will...

Here's what I have... Let me know what you think...

Again, point me in another direction if I have it all wrong... Thanks guys!

Just seeing what you guys think? It'll either be welded to my expo spring plates I have in the garage, or they'll have tabs on them that will bolt on top of the plate under the the u-bolt nuts... Haven't decided that yet...

I decided to go with heim joints so I still have pivoting action when flexing, but this will keep the axle stationary in the y-axis, if you will...

Here's what I have... Let me know what you think...

Again, point me in another direction if I have it all wrong... Thanks guys!

#5

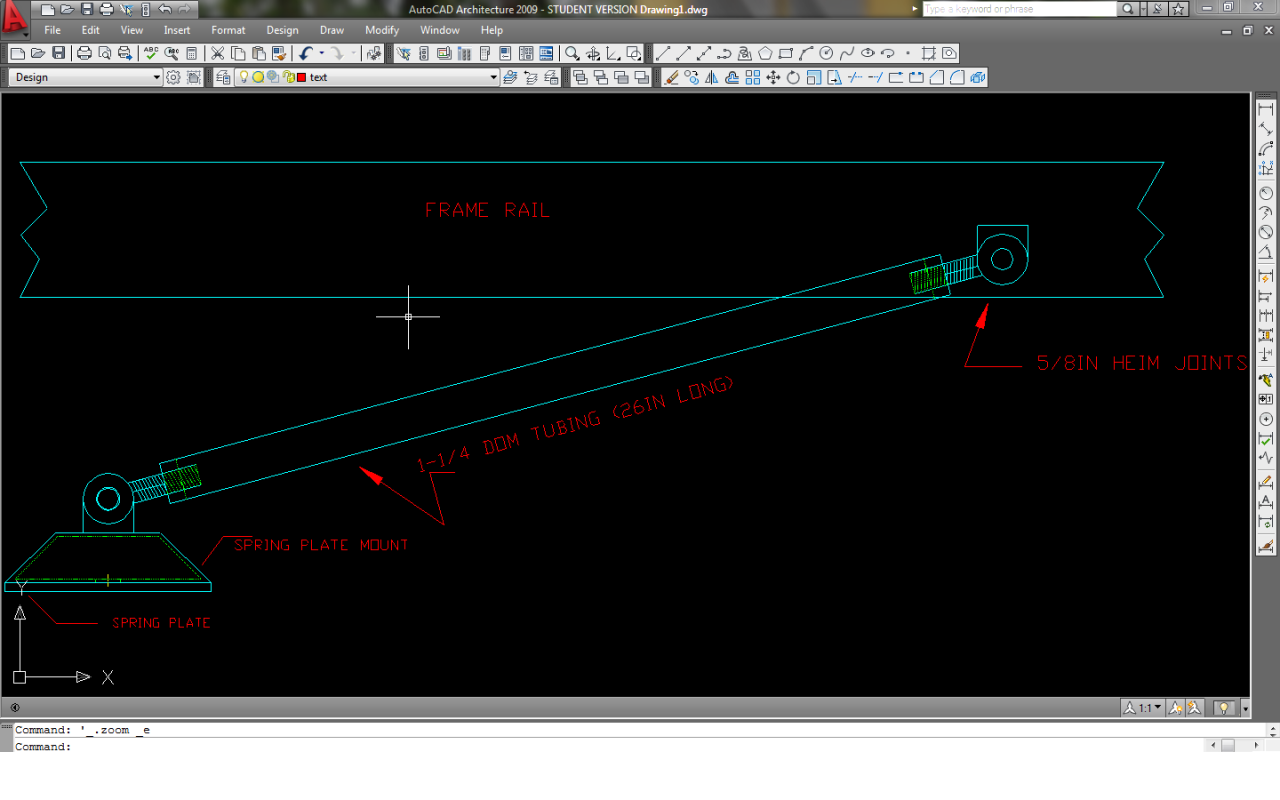

I've been told to run a piece of DOM with a bushing and a sleeve on the spring plate end and a HEIM on the spring hangar side where it'll mount to the hangar. The bushing will provide some movement so it doesn't bind up... So I'll mock it up tomorrow and see what happens....

#8

Ladder bar = traction bar

Yeah... It's more so for street use to help with axle wrap. Going to make them easy to take on and off in extreme cases of flexing... Which hardly ever happens... I'm a snow wheeler now.

Yeah... It's more so for street use to help with axle wrap. Going to make them easy to take on and off in extreme cases of flexing... Which hardly ever happens... I'm a snow wheeler now.

#10

That's what I'll be doing I think... Cept a heim joint where there is just a stud with bushings... I dunno, I'm bored in my fab class, And thought this would be a good thing to build, so I don't horseshoe my leaf springs again.

I'll probably copy Bob's Duff bar design he's got... Seems simple... Thanks Andrew for the help too.

I'll probably copy Bob's Duff bar design he's got... Seems simple... Thanks Andrew for the help too.

#12

Ok, so I'm going to follow what Matt said, slip and twist design...

One end of the heim will get 1.5 DOM tubing, bout 20in long...

The other end will get a heim also with 1.25 DOM tubing, 20in long...

Leaving 6in in the middle for play... Or should I leave more room for travel...

On end will get a zyrc fitting for grease to allow the slide to happen easily when the truck is tucking and flexing... 1/4in plate mounts will mount to the existing square tubing I have made...

Using the CNC again today... I love that thing!

One end of the heim will get 1.5 DOM tubing, bout 20in long...

The other end will get a heim also with 1.25 DOM tubing, 20in long...

Leaving 6in in the middle for play... Or should I leave more room for travel...

On end will get a zyrc fitting for grease to allow the slide to happen easily when the truck is tucking and flexing... 1/4in plate mounts will mount to the existing square tubing I have made...

Using the CNC again today... I love that thing!

#13

It seems to me that you would want more leverage on that spring plate mount. If the heim mount is higher up, you'll get more leverage and less axle wrap.

This design doesn't make sense with a "slip and twist". The only reason you are resisting the axle wrap is because that link is (relatively) solid. You might as well tie a rope between the mounts. Unless you are planning to have a pin that locks it tight and is removable. In which case, it is like warrior products torque bars, except with a heim and with twist.

http://www.warriorproducts.com/catal...orqueBarz.html

This design doesn't make sense with a "slip and twist". The only reason you are resisting the axle wrap is because that link is (relatively) solid. You might as well tie a rope between the mounts. Unless you are planning to have a pin that locks it tight and is removable. In which case, it is like warrior products torque bars, except with a heim and with twist.

http://www.warriorproducts.com/catal...orqueBarz.html

#14

if it were me, and im considering doing this to my duff bars but what do you think about fabbing up hiems on both ends of the bar. i dont like the bushing/sleave setup on the end of the bar over the axle. also the duff style setup doesnt limit my flex too much, if anything it protects my rear fenders from damage bacause i cant quite tuck anymore.

#15

axle wrap is the axle rotating.. there for trying move the pieces of tube up and down, not forward and back.

don't just do 2 pieces of tube inside each other, have one piece come off the top of the axle, this is the one that the forward piece will slip into, then have another tube come off the bottom of the axle and make it as long as you can.

your gonna want this as close to the middle of the axle as you can get it.

you can also make it with a shackle on the front instead.

no need to lock it, then theres absolutly no reason to have the whole sliding part... because you would always need it locked.

don't just do 2 pieces of tube inside each other, have one piece come off the top of the axle, this is the one that the forward piece will slip into, then have another tube come off the bottom of the axle and make it as long as you can.

your gonna want this as close to the middle of the axle as you can get it.

you can also make it with a shackle on the front instead.

no need to lock it, then theres absolutly no reason to have the whole sliding part... because you would always need it locked.

#16

http://www.ruffstuffspecialties.com/...tem-p-168.html

buy that from them ^^

or one of these if you wanna use heims.

http://www.ruffstuffspecialties.com/...tes-p-165.html

http://www.ruffstuffspecialties.com/...nal-p-244.html

and build it like this, just make sure you get the bottom piece as long as you can, unlike this one haha. By putting it right next to the pumpkin you don't need to run 2, if you put it out by the leaf springs your gonna need one for each side.

read this, and the links to pirate in it.

https://www.ranger-forums.com/forum2...ad.php?t=83212

buy that from them ^^

or one of these if you wanna use heims.

http://www.ruffstuffspecialties.com/...tes-p-165.html

http://www.ruffstuffspecialties.com/...nal-p-244.html

and build it like this, just make sure you get the bottom piece as long as you can, unlike this one haha. By putting it right next to the pumpkin you don't need to run 2, if you put it out by the leaf springs your gonna need one for each side.

read this, and the links to pirate in it.

https://www.ranger-forums.com/forum2...ad.php?t=83212

#19

Tre, where do you plan on mounting the single end on the axle?

i THINK its gotta at axle centerline?

just do a second bar, one on top of the axle, one under. it'll work better and be a HELL of a long stronger.

i THINK its gotta at axle centerline?

just do a second bar, one on top of the axle, one under. it'll work better and be a HELL of a long stronger.

#22

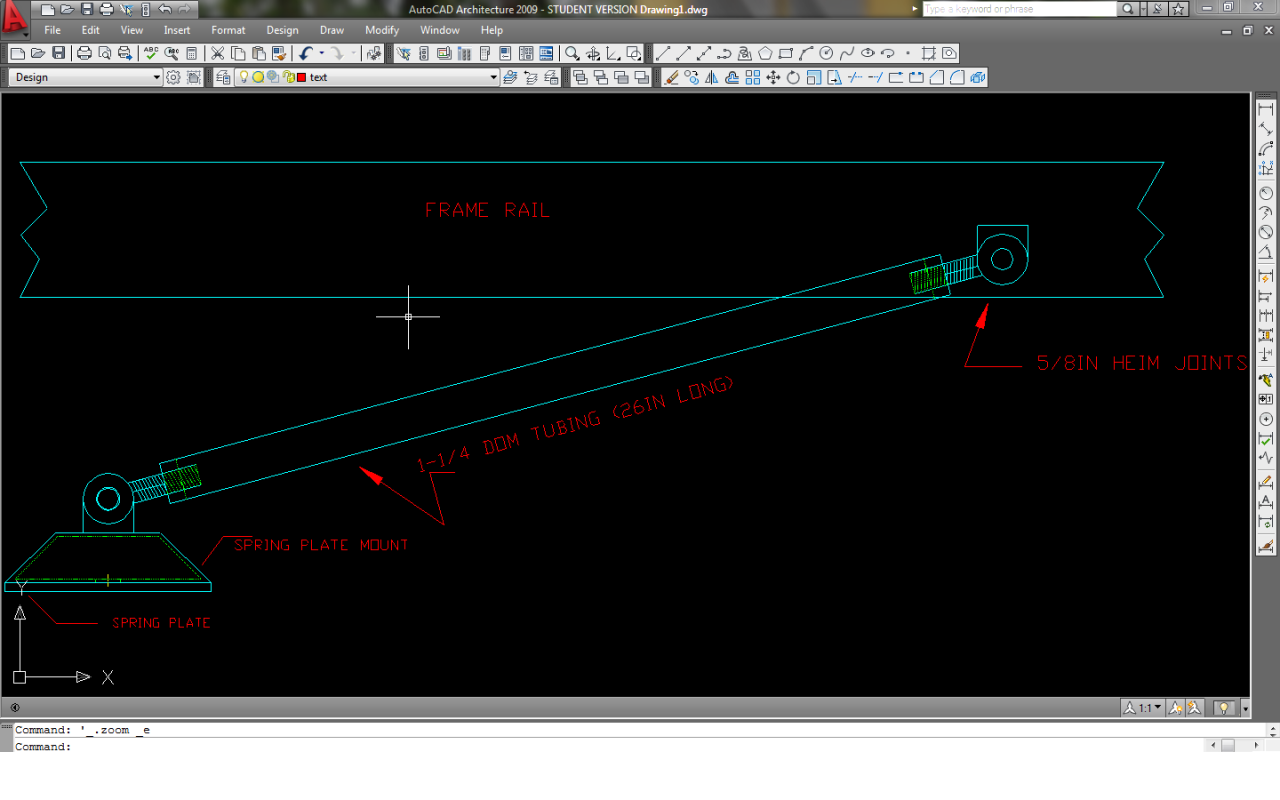

The thing the tubes are mounted to, mount on top of the spring plate through the U-bolts, like the duff bars..

The fit up is almost hairline in the tubes... There's such minimal amount that it creates compression, a small amount... It will get a grease fitting on the big tube and filled with grease.

One on each side of the truck, like the duff bars also...

Keep in mind guys, I have limited resources, and running out of time before summer, but like I was telling Andrew, maybe the goal is to reduce axle wrap, rather than eliminate it... The top hangar will be right above the spring hangar coming off the frame allowing enough room during flex that it won't hit.

The fit up is almost hairline in the tubes... There's such minimal amount that it creates compression, a small amount... It will get a grease fitting on the big tube and filled with grease.

One on each side of the truck, like the duff bars also...

Keep in mind guys, I have limited resources, and running out of time before summer, but like I was telling Andrew, maybe the goal is to reduce axle wrap, rather than eliminate it... The top hangar will be right above the spring hangar coming off the frame allowing enough room during flex that it won't hit.

#25

Those are not going to do anything to reduce axle wrap. How do you not see that?

I mean it all looks good, but it don't do anything. Allowing the tube to extend/collapse completely defeats the purpose.

If you had one tube below, and one above the axle, and those two welded together, with the forward piece being a slip and twist it would help.

But with a single tube it is pointless and ineffective.

Go back to the original plan with one solid tube, or put one above the axle and one below.

I mean it all looks good, but it don't do anything. Allowing the tube to extend/collapse completely defeats the purpose.

If you had one tube below, and one above the axle, and those two welded together, with the forward piece being a slip and twist it would help.

But with a single tube it is pointless and ineffective.

Go back to the original plan with one solid tube, or put one above the axle and one below.