How-To: Change a DOHC 2.3L PCV Valve

#1

How-To: Change a DOHC 2.3L PCV Valve

How to change a PCV valve in b2300 or Ford Ranger. I wrote this up after some misinformation and hope this makes go easier for you!

You will need:

• 7/32” socket

• 1/2 “ socket

• 8mm socket

• socket extensions (12”-28”, whatever you have)

• Jack Stand

• Jack

• 19mm socket for wheel lugs

• Vaseline

• garden hose

• Power Drill

• Ύ” spade bit

1. Undo the Neg. lead on the battery. (Do this to avoid engaging the starter motor with the metal socket extensions.)

2. Jack up the drivers side front and place on jack stand. Undo lug nuts (but do not remove!) before jacking up.

3. Take the lug nuts off and remove wheel.

4. Using the 7/32” wrench/ socket, undo the 3 bolts along the edge of the fender flare.

5. Undo the 2 larger (unsure of size) bolts roughly underneath the headlights.

6. Undo the mud flap (if equipped) with an 8mm socket.

7. Remove mud flap.

8. Directly above the wheel will be (one) ½” nut. Remove this.

9. If there are any barbed connections on the inside of the engine compartment, pull them out of the plastic spray guard.

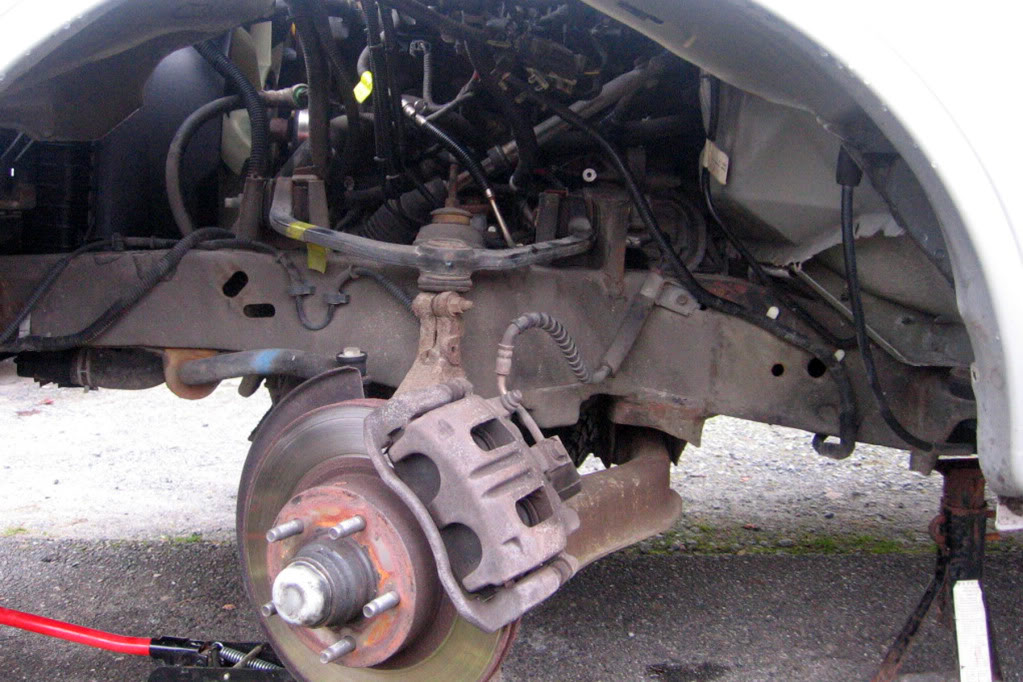

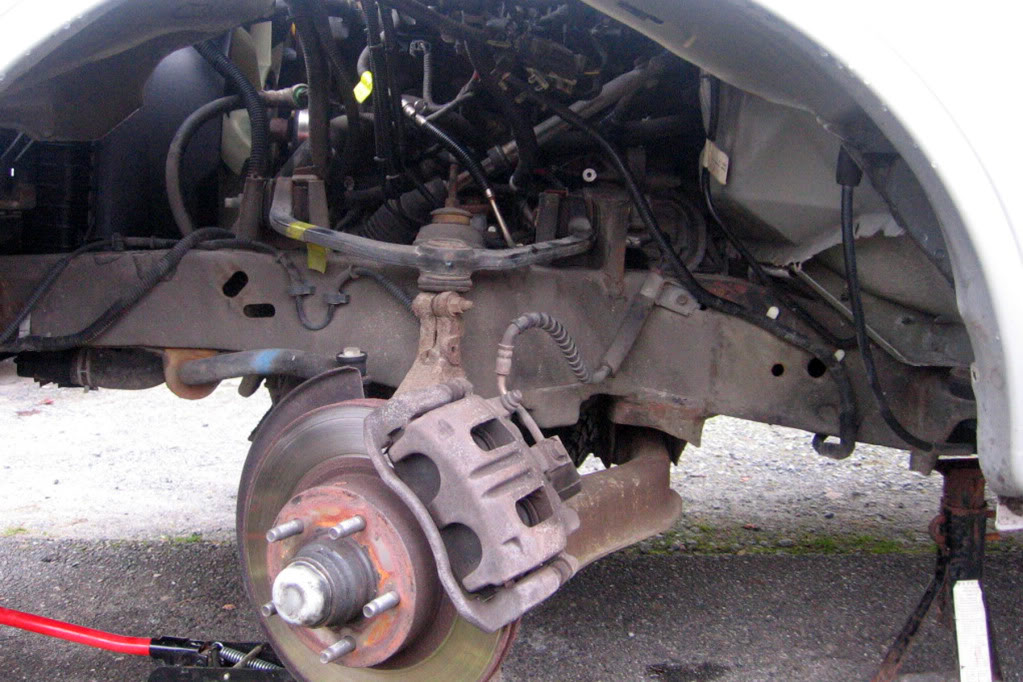

10. The plastic splashguard is now ready for removal. Manipulate it until it comes out, and make sure none of the bolt clips come off in the process. See photo 1.

11. You will notice that there is a LOT of sand and crap caught in the recess of the splashguard that juts down at the lowest point of the fender, just above where the mud flap sits. Clean this out. See photo 2 and 3.

12. Drill 3 - Ύ” holes in this recess using the spade bits and power drill. This will help in preventing rust forming at the bottom of the fender. While you are at it, hose out any dirt on the fender bottom. See photo 4.

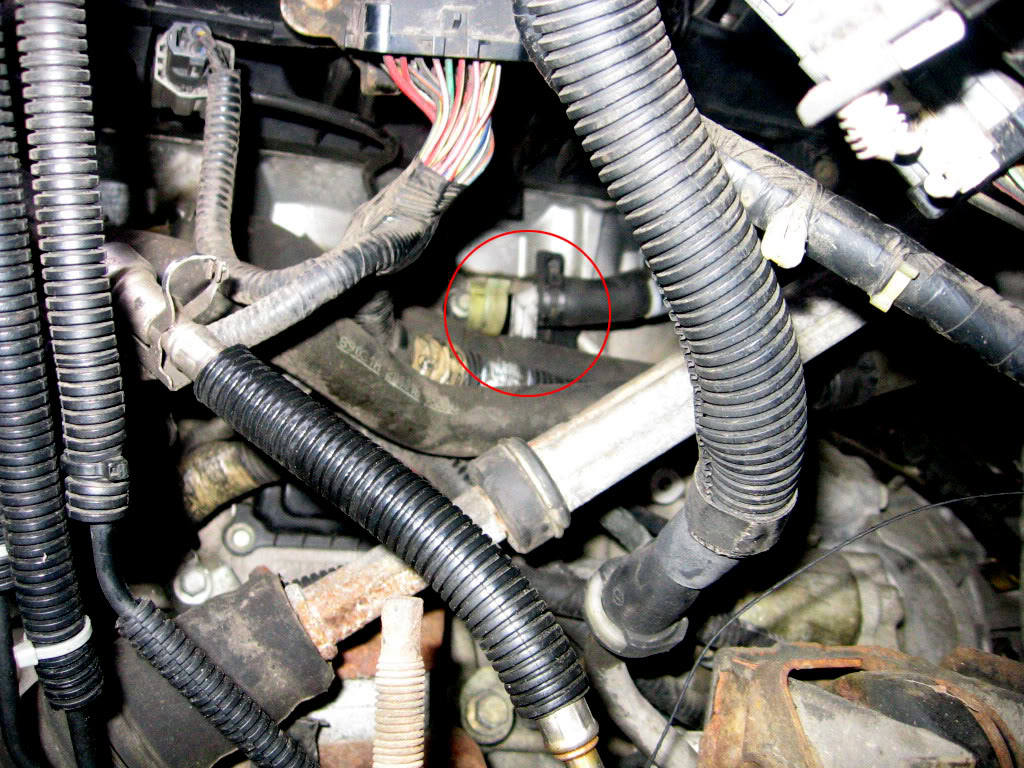

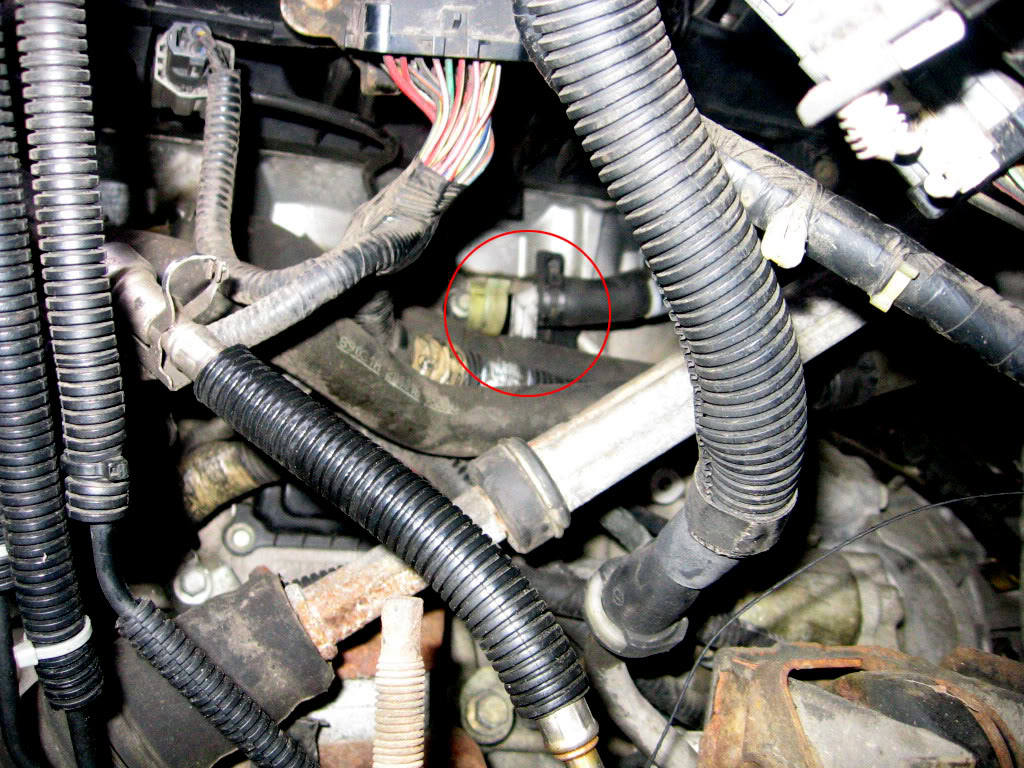

13. Identify the PCV valve (circled in red). It is hard to see, but look for light grey plastic. It will be attached to the black breather assembly that is attached to the engine block directly behind the steering column. See photo 5.

14. Using pliers, or strong fingers, move the hose clamp along the hose towards the firewall, and pull the hose off the PCV valve.

15. DO NOT ATTEMPT TO PULL, PRY, or DISRUPT THE PCV VALVE! As per govt. regulations, most models, especially later years, will have a retention device!

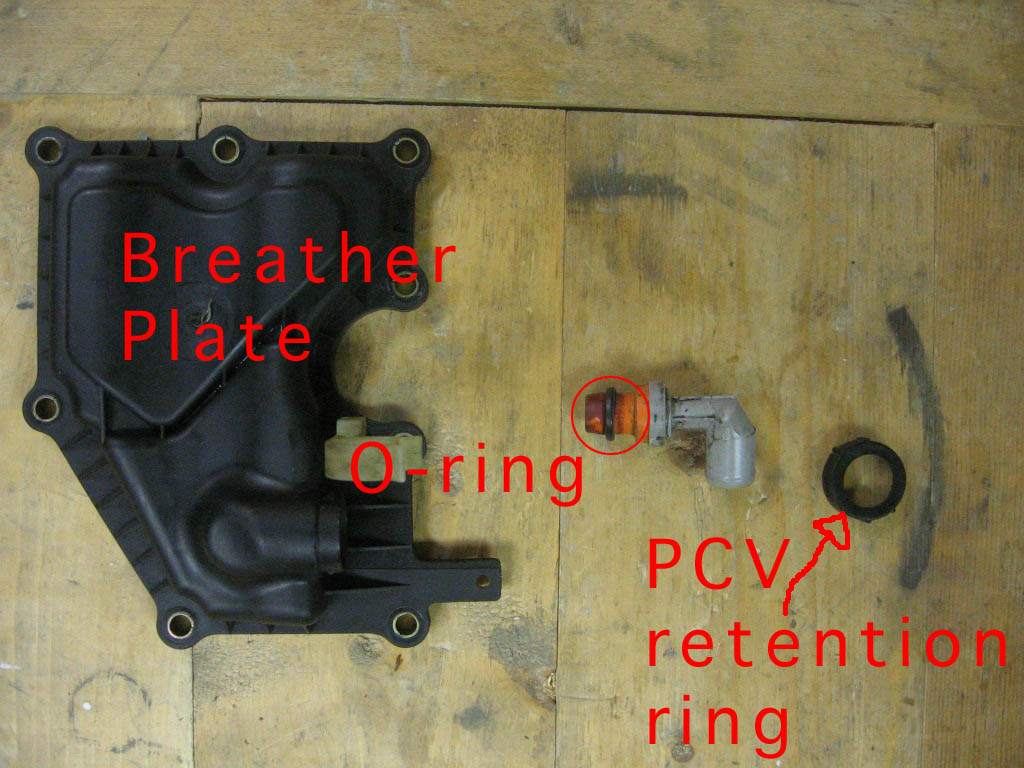

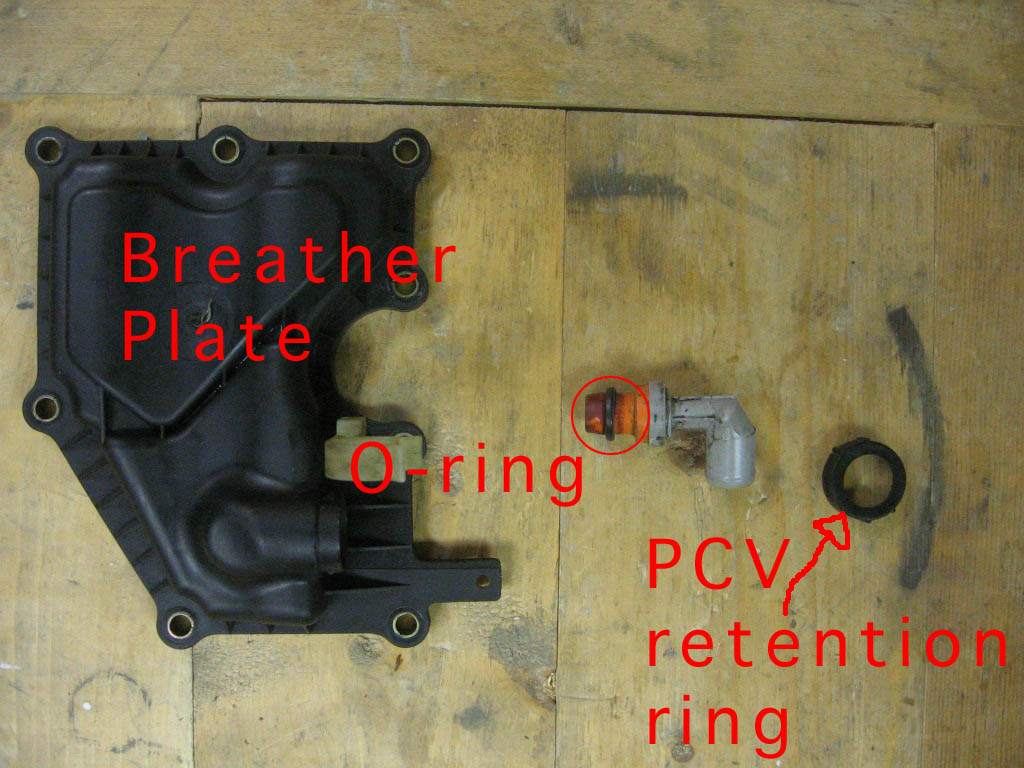

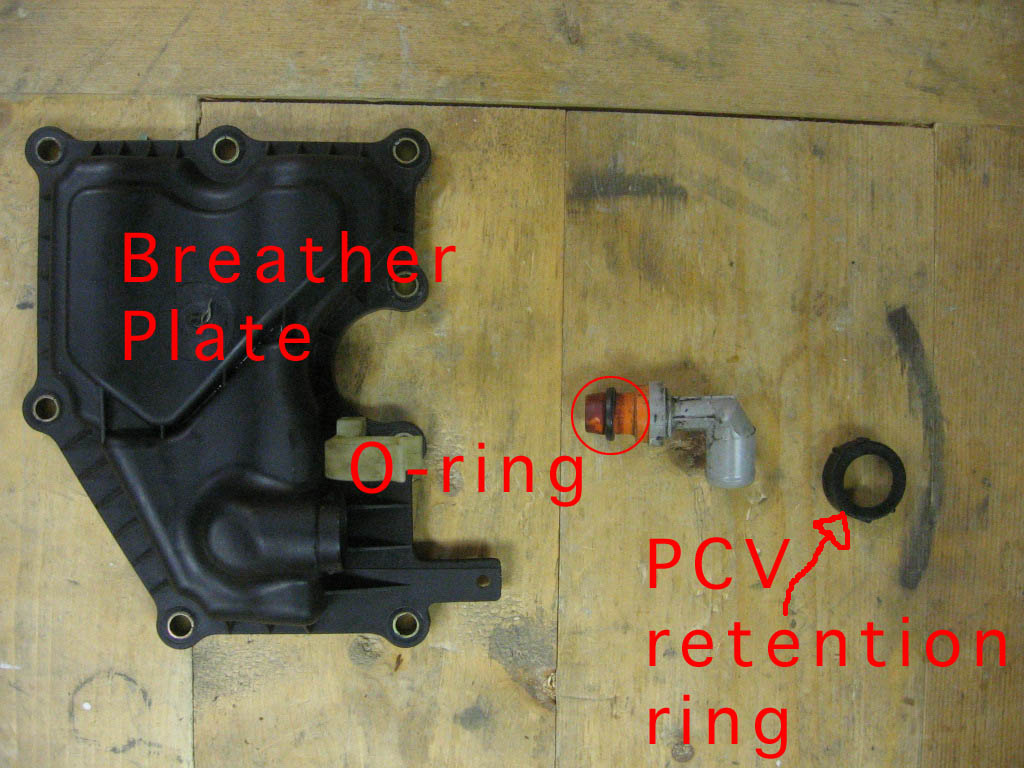

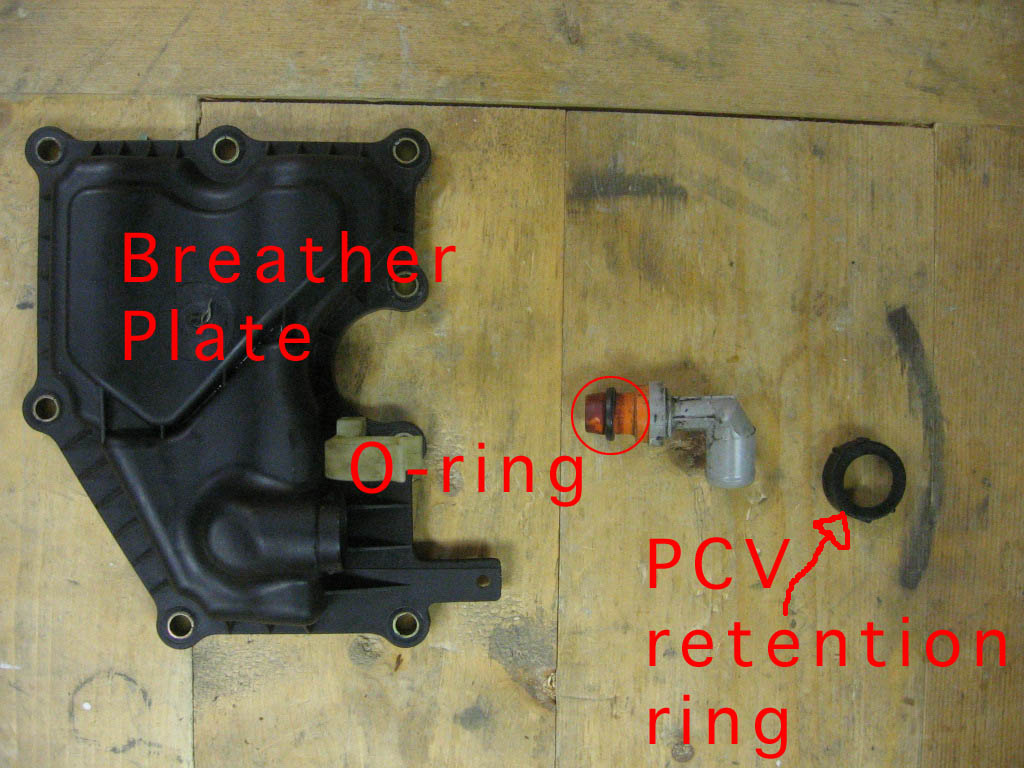

16. Using an 8mm socket attached to extensions, start undoing the first of 8 8mm bolts that hold the breather assembly to the side of the engine block. You may have to move some wiring harnesses and plumbing. Photo 6 is a photo of all the parts.

17. These will be torqued to about 10-15 ft/lbs, and should come out easily.

18. Remove the breather plate from the engine block.

19. Clean the breather assembly, and carefully remove the black cap that retains the PCV valve. You cannot remove the PCV valve without removing this first. Use a pen knife and work carefully. This is a $15 part from Ford. That’s a lot of beer!

20. If you crack this, you can reassemble it with two-part epoxy. Or buy a new one.

21. Now the PCV valve will pull out. Pull it out.

22. Remove the rubber o-ring from the PCV valve, and retain, it is not included with new valves!

23. I personally would replace the valve, regardless of condition, alternately; you can clean with intake manifold cleaner. Seriously. You have done this much work; it’s time for a new valve.

24. Place o-ring on new PCV valve and insert in breather.

25. Place lock ring do-hickey on breather over PCV valve, and snap into place.

26. Manipulate Breather assembly back through maze of wire in wheel well and up against block.

27. Using a diagonal tightening pattern, tighten the 8mm bolts HAND TIGHT! (Using the socket extensions.) They do not need to be more than 15 ft/lbs.

28. Attach the hose to the PCV valve and slide the hose clamp over the PCV valve.

29. Put all hoses and wiring harnesses back into place.

30. Manipulate the splash guard back into place under the wheel well, and attach all bolts that you had to take out. (I would coat the bolts in Vaseline to ease in removal next time.)

31. Put the mud flap back in place and bolt it up.

32. Insert barbed wiring harnesses into the splash guard on the inside of the engine bay.

33. Re-connect the negative battery cable.

34. Re-install front wheel and put on lug nuts. Tighten while holding wheel from spinning.

35. Lower vehicle.

36. Tighten lug nuts.

37. Yeah Baby! Done!

You will need:

• 7/32” socket

• 1/2 “ socket

• 8mm socket

• socket extensions (12”-28”, whatever you have)

• Jack Stand

• Jack

• 19mm socket for wheel lugs

• Vaseline

• garden hose

• Power Drill

• Ύ” spade bit

1. Undo the Neg. lead on the battery. (Do this to avoid engaging the starter motor with the metal socket extensions.)

2. Jack up the drivers side front and place on jack stand. Undo lug nuts (but do not remove!) before jacking up.

3. Take the lug nuts off and remove wheel.

4. Using the 7/32” wrench/ socket, undo the 3 bolts along the edge of the fender flare.

5. Undo the 2 larger (unsure of size) bolts roughly underneath the headlights.

6. Undo the mud flap (if equipped) with an 8mm socket.

7. Remove mud flap.

8. Directly above the wheel will be (one) ½” nut. Remove this.

9. If there are any barbed connections on the inside of the engine compartment, pull them out of the plastic spray guard.

10. The plastic splashguard is now ready for removal. Manipulate it until it comes out, and make sure none of the bolt clips come off in the process. See photo 1.

11. You will notice that there is a LOT of sand and crap caught in the recess of the splashguard that juts down at the lowest point of the fender, just above where the mud flap sits. Clean this out. See photo 2 and 3.

12. Drill 3 - Ύ” holes in this recess using the spade bits and power drill. This will help in preventing rust forming at the bottom of the fender. While you are at it, hose out any dirt on the fender bottom. See photo 4.

13. Identify the PCV valve (circled in red). It is hard to see, but look for light grey plastic. It will be attached to the black breather assembly that is attached to the engine block directly behind the steering column. See photo 5.

14. Using pliers, or strong fingers, move the hose clamp along the hose towards the firewall, and pull the hose off the PCV valve.

15. DO NOT ATTEMPT TO PULL, PRY, or DISRUPT THE PCV VALVE! As per govt. regulations, most models, especially later years, will have a retention device!

16. Using an 8mm socket attached to extensions, start undoing the first of 8 8mm bolts that hold the breather assembly to the side of the engine block. You may have to move some wiring harnesses and plumbing. Photo 6 is a photo of all the parts.

17. These will be torqued to about 10-15 ft/lbs, and should come out easily.

18. Remove the breather plate from the engine block.

19. Clean the breather assembly, and carefully remove the black cap that retains the PCV valve. You cannot remove the PCV valve without removing this first. Use a pen knife and work carefully. This is a $15 part from Ford. That’s a lot of beer!

20. If you crack this, you can reassemble it with two-part epoxy. Or buy a new one.

21. Now the PCV valve will pull out. Pull it out.

22. Remove the rubber o-ring from the PCV valve, and retain, it is not included with new valves!

23. I personally would replace the valve, regardless of condition, alternately; you can clean with intake manifold cleaner. Seriously. You have done this much work; it’s time for a new valve.

24. Place o-ring on new PCV valve and insert in breather.

25. Place lock ring do-hickey on breather over PCV valve, and snap into place.

26. Manipulate Breather assembly back through maze of wire in wheel well and up against block.

27. Using a diagonal tightening pattern, tighten the 8mm bolts HAND TIGHT! (Using the socket extensions.) They do not need to be more than 15 ft/lbs.

28. Attach the hose to the PCV valve and slide the hose clamp over the PCV valve.

29. Put all hoses and wiring harnesses back into place.

30. Manipulate the splash guard back into place under the wheel well, and attach all bolts that you had to take out. (I would coat the bolts in Vaseline to ease in removal next time.)

31. Put the mud flap back in place and bolt it up.

32. Insert barbed wiring harnesses into the splash guard on the inside of the engine bay.

33. Re-connect the negative battery cable.

34. Re-install front wheel and put on lug nuts. Tighten while holding wheel from spinning.

35. Lower vehicle.

36. Tighten lug nuts.

37. Yeah Baby! Done!

Last edited by zabeard; 12-22-2010 at 08:22 PM.

The following users liked this post:

Veganman (06-17-2024)

#4

#6

How to change a PCV valve in b2300 or Ford Ranger. I wrote this up after some misinformation and hope this makes go easier for you!

You will need:

7/32 socket

1/2 socket

8mm socket

socket extensions (12-28, whatever you have)

Jack Stand

Jack

19mm socket for wheel lugs

Vaseline

garden hose

Power Drill

Ύ spade bit

1. Undo the Neg. lead on the battery. (Do this to avoid engaging the starter motor with the metal socket extensions.)

2. Jack up the drivers side front and place on jack stand. Undo lug nuts (but do not remove!) before jacking up.

3. Take the lug nuts off and remove wheel.

4. Using the 7/32 wrench/ socket, undo the 3 bolts along the edge of the fender flare.

5. Undo the 2 larger (unsure of size) bolts roughly underneath the headlights.

6. Undo the mud flap (if equipped) with an 8mm socket.

7. Remove mud flap.

8. Directly above the wheel will be (one) ½ nut. Remove this.

9. If there are any barbed connections on the inside of the engine compartment, pull them out of the plastic spray guard.

10. The plastic splashguard is now ready for removal. Manipulate it until it comes out, and make sure none of the bolt clips come off in the process. See photo 1.

11. You will notice that there is a LOT of sand and crap caught in the recess of the splashguard that juts down at the lowest point of the fender, just above where the mud flap sits. Clean this out. See photo 2 and 3.

12. Drill 3 - Ύ holes in this recess using the spade bits and power drill. This will help in preventing rust forming at the bottom of the fender. While you are at it, hose out any dirt on the fender bottom. See photo 4.

13. Identify the PCV valve (circled in red). It is hard to see, but look for light grey plastic. It will be attached to the black breather assembly that is attached to the engine block directly behind the steering column. See photo 5.

14. Using pliers, or strong fingers, move the hose clamp along the hose towards the firewall, and pull the hose off the PCV valve.

15. DO NOT ATTEMPT TO PULL, PRY, or DISRUPT THE PCV VALVE! As per govt. regulations, most models, especially later years, will have a retention device!

16. Using an 8mm socket attached to extensions, start undoing the first of 8 8mm bolts that hold the breather assembly to the side of the engine block. You may have to move some wiring harnesses and plumbing. Photo 6 is a photo of all the parts.

17. These will be torqued to about 10-15 ft/lbs, and should come out easily.

18. Remove the breather plate from the engine block.

19. Clean the breather assembly, and carefully remove the black cap that retains the PCV valve. You cannot remove the PCV valve without removing this first. Use a pen knife and work carefully. This is a $15 part from Ford. Thats a lot of beer!

20. If you crack this, you can reassemble it with two-part epoxy. Or buy a new one.

21. Now the PCV valve will pull out. Pull it out.

22. Remove the rubber o-ring from the PCV valve, and retain, it is not included with new valves!

23. I personally would replace the valve, regardless of condition, alternately; you can clean with intake manifold cleaner. Seriously. You have done this much work; its time for a new valve.

24. Place o-ring on new PCV valve and insert in breather.

25. Place lock ring do-hickey on breather over PCV valve, and snap into place.

26. Manipulate Breather assembly back through maze of wire in wheel well and up against block.

27. Using a diagonal tightening pattern, tighten the 8mm bolts HAND TIGHT! (Using the socket extensions.) They do not need to be more than 15 ft/lbs.

28. Attach the hose to the PCV valve and slide the hose clamp over the PCV valve.

29. Put all hoses and wiring harnesses back into place.

30. Manipulate the splash guard back into place under the wheel well, and attach all bolts that you had to take out. (I would coat the bolts in Vaseline to ease in removal next time.)

31. Put the mud flap back in place and bolt it up.

32. Insert barbed wiring harnesses into the splash guard on the inside of the engine bay.

33. Re-connect the negative battery cable.

34. Re-install front wheel and put on lug nuts. Tighten while holding wheel from spinning.

35. Lower vehicle.

36. Tighten lug nuts.

37. Yeah Baby! Done!

You will need:

7/32 socket

1/2 socket

8mm socket

socket extensions (12-28, whatever you have)

Jack Stand

Jack

19mm socket for wheel lugs

Vaseline

garden hose

Power Drill

Ύ spade bit

1. Undo the Neg. lead on the battery. (Do this to avoid engaging the starter motor with the metal socket extensions.)

2. Jack up the drivers side front and place on jack stand. Undo lug nuts (but do not remove!) before jacking up.

3. Take the lug nuts off and remove wheel.

4. Using the 7/32 wrench/ socket, undo the 3 bolts along the edge of the fender flare.

5. Undo the 2 larger (unsure of size) bolts roughly underneath the headlights.

6. Undo the mud flap (if equipped) with an 8mm socket.

7. Remove mud flap.

8. Directly above the wheel will be (one) ½ nut. Remove this.

9. If there are any barbed connections on the inside of the engine compartment, pull them out of the plastic spray guard.

10. The plastic splashguard is now ready for removal. Manipulate it until it comes out, and make sure none of the bolt clips come off in the process. See photo 1.

11. You will notice that there is a LOT of sand and crap caught in the recess of the splashguard that juts down at the lowest point of the fender, just above where the mud flap sits. Clean this out. See photo 2 and 3.

12. Drill 3 - Ύ holes in this recess using the spade bits and power drill. This will help in preventing rust forming at the bottom of the fender. While you are at it, hose out any dirt on the fender bottom. See photo 4.

13. Identify the PCV valve (circled in red). It is hard to see, but look for light grey plastic. It will be attached to the black breather assembly that is attached to the engine block directly behind the steering column. See photo 5.

14. Using pliers, or strong fingers, move the hose clamp along the hose towards the firewall, and pull the hose off the PCV valve.

15. DO NOT ATTEMPT TO PULL, PRY, or DISRUPT THE PCV VALVE! As per govt. regulations, most models, especially later years, will have a retention device!

16. Using an 8mm socket attached to extensions, start undoing the first of 8 8mm bolts that hold the breather assembly to the side of the engine block. You may have to move some wiring harnesses and plumbing. Photo 6 is a photo of all the parts.

17. These will be torqued to about 10-15 ft/lbs, and should come out easily.

18. Remove the breather plate from the engine block.

19. Clean the breather assembly, and carefully remove the black cap that retains the PCV valve. You cannot remove the PCV valve without removing this first. Use a pen knife and work carefully. This is a $15 part from Ford. Thats a lot of beer!

20. If you crack this, you can reassemble it with two-part epoxy. Or buy a new one.

21. Now the PCV valve will pull out. Pull it out.

22. Remove the rubber o-ring from the PCV valve, and retain, it is not included with new valves!

23. I personally would replace the valve, regardless of condition, alternately; you can clean with intake manifold cleaner. Seriously. You have done this much work; its time for a new valve.

24. Place o-ring on new PCV valve and insert in breather.

25. Place lock ring do-hickey on breather over PCV valve, and snap into place.

26. Manipulate Breather assembly back through maze of wire in wheel well and up against block.

27. Using a diagonal tightening pattern, tighten the 8mm bolts HAND TIGHT! (Using the socket extensions.) They do not need to be more than 15 ft/lbs.

28. Attach the hose to the PCV valve and slide the hose clamp over the PCV valve.

29. Put all hoses and wiring harnesses back into place.

30. Manipulate the splash guard back into place under the wheel well, and attach all bolts that you had to take out. (I would coat the bolts in Vaseline to ease in removal next time.)

31. Put the mud flap back in place and bolt it up.

32. Insert barbed wiring harnesses into the splash guard on the inside of the engine bay.

33. Re-connect the negative battery cable.

34. Re-install front wheel and put on lug nuts. Tighten while holding wheel from spinning.

35. Lower vehicle.

36. Tighten lug nuts.

37. Yeah Baby! Done!

#8

In your post you mentioned the epoxy as a way to repair the PCV Retaining ring.

I just wanna to put everything back since I already remove the Breather and the PCV Valve which finally came out by just twisting a little bit and then pull it.I guess the twisting did the job of unstucking it from the hose.The breakage it is very small.There's some epoxy around and I really need just to put back the PCV Valve so I can run some other tests.All started when I run out of gas and after filling it up it would run but then after turning off and then tried to started again it won't start.I changed the fuel filter and the fuel pump works. I disconnected the batery cable so to reset the iddle data.After that I run the truck at 50~60 several miles and after that let it sit for a couple of hours, after that I swich it on but it won't start.Any idea?

I just wanna to put everything back since I already remove the Breather and the PCV Valve which finally came out by just twisting a little bit and then pull it.I guess the twisting did the job of unstucking it from the hose.The breakage it is very small.There's some epoxy around and I really need just to put back the PCV Valve so I can run some other tests.All started when I run out of gas and after filling it up it would run but then after turning off and then tried to started again it won't start.I changed the fuel filter and the fuel pump works. I disconnected the batery cable so to reset the iddle data.After that I run the truck at 50~60 several miles and after that let it sit for a couple of hours, after that I swich it on but it won't start.Any idea?

#9

#11

Wow, thank you very much for the detailed instructions! I had a heck of a time replacing the PCV valve because the hose clamps were pointed toward the engine, and it was absolutely impossible to get at them. I finally had to get a long knife and cut the hose in half, which allowed me to remove the breather plate along with the PCV valve. Then I had to drive to the auto parts store to get a 3" piece of hose to replace the one I cut in two. I don't know what in the world Ford was thinking when they decided to put the PCV valve in such a horrid spot! My truck has 146,000 miles and the valve had never been replaced. I hope I never have to replace it again! Of course, if I had access to a lift, this job would have been easier.

Last edited by Veganman; 06-17-2024 at 04:42 PM. Reason: Additional comments...

Thread

Thread Starter

Forum

Replies

Last Post