Going with electric fans for the radiator on my '02

#1

Going with electric fans for the radiator on my '02

Finally got some time today to finish up my electric fan install: Astonishing how much noise went away with the OEM fan!

Used a pair of RapidCool 12" fans, each rated at 1650 CFM, a trio of 70 amp SPDT relays, a Ford Windstar a/c pressure switch and a early BMW Z3 4 cyl temp switch.

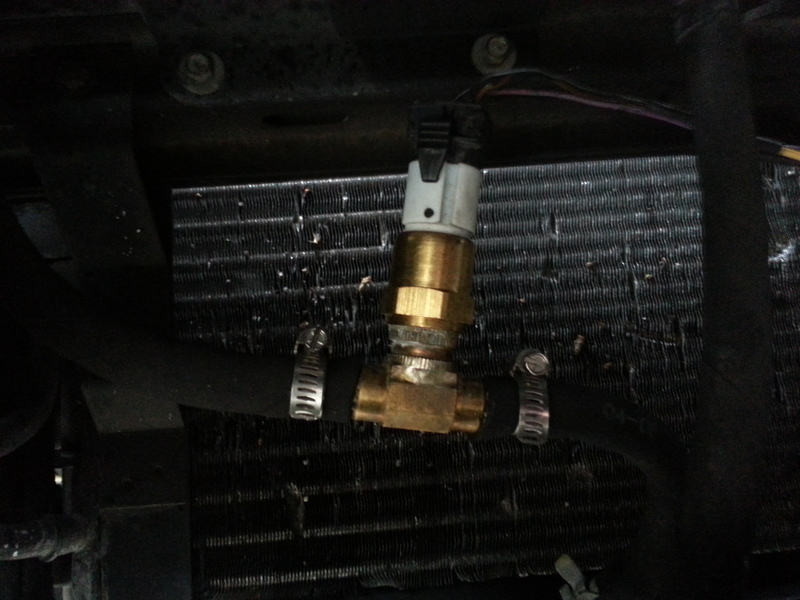

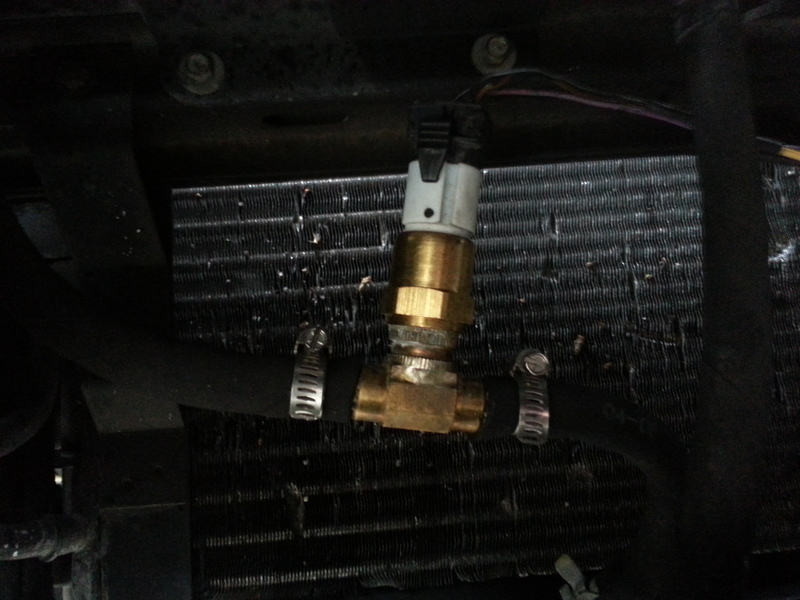

The temp switch is an 80°/88°C switch (176°/190°F). Used a brass bung cut from a BMW radiator, a 1/4" brass T fitting and a couple hose barbs all silver soldered together. The sensor is on the radiator's transmission cooler outlet line. Because of the fluid to fluid heat exchange, the outlet from the cooler should be a very accurate indication of the radiator's outlet water temp. Still, to play is safe, I used the lowest temp sensor I could find. Had I mounted the temp switch on the intake manifold, I'd have used a higher temp switch.

Shell of the fan is 1 1/2" aluminum angle riveted to an aluminum plate, made the upper left mounting ear removable to more easily clear the trans cooler inlet.

Made some air flaps so while cruising down the highway, excess air can escape into the engine bay, but if the fans kick on, the flaps will be "sucked shut".

Installed a divider between the two fans. Should one die, the other will still be able to draw air through the radiator rather than in through the dead fan.

Each fan is separately fused, if one fan does die, only the high temp switch or high pressure switch will kick on the one fan, but that's better than total cooling failure.

I'd kept a leaking V8 radiator just for the fit and dimensions, made the day of install an all but "drop in" event.

Used a body to hood seal from a BMW 5 series to seal the fan assembly to the radiator.

Yea, it's TIGHT in there! Had to trim off the original fan clutch stub on the water pump!

Temp switch:

A quick test before install:

Backside detail:

The 3300 CFM should be more than enough, even in traffic today in 90°F heat, no issues with the A/C or engine temp. I'd have loved to move more like 4500 CFM but a pair of 12's was the largest I could fit so that's what I went with.

The one component I'm really unhappy with is the a/c high pressure switch. It's rated at something like 350 PSI, a bit high for my liking, might try a klixon type snap on temp switch on the condenser outlet. A 145° close, 135° open would help keep the high pressure below 250 psi. A 150/135 is easy to find, but would let the pressures rise to over 260 psi before closing.

Used a pair of RapidCool 12" fans, each rated at 1650 CFM, a trio of 70 amp SPDT relays, a Ford Windstar a/c pressure switch and a early BMW Z3 4 cyl temp switch.

The temp switch is an 80°/88°C switch (176°/190°F). Used a brass bung cut from a BMW radiator, a 1/4" brass T fitting and a couple hose barbs all silver soldered together. The sensor is on the radiator's transmission cooler outlet line. Because of the fluid to fluid heat exchange, the outlet from the cooler should be a very accurate indication of the radiator's outlet water temp. Still, to play is safe, I used the lowest temp sensor I could find. Had I mounted the temp switch on the intake manifold, I'd have used a higher temp switch.

Shell of the fan is 1 1/2" aluminum angle riveted to an aluminum plate, made the upper left mounting ear removable to more easily clear the trans cooler inlet.

Made some air flaps so while cruising down the highway, excess air can escape into the engine bay, but if the fans kick on, the flaps will be "sucked shut".

Installed a divider between the two fans. Should one die, the other will still be able to draw air through the radiator rather than in through the dead fan.

Each fan is separately fused, if one fan does die, only the high temp switch or high pressure switch will kick on the one fan, but that's better than total cooling failure.

I'd kept a leaking V8 radiator just for the fit and dimensions, made the day of install an all but "drop in" event.

Used a body to hood seal from a BMW 5 series to seal the fan assembly to the radiator.

Yea, it's TIGHT in there! Had to trim off the original fan clutch stub on the water pump!

Temp switch:

A quick test before install:

Backside detail:

The 3300 CFM should be more than enough, even in traffic today in 90°F heat, no issues with the A/C or engine temp. I'd have loved to move more like 4500 CFM but a pair of 12's was the largest I could fit so that's what I went with.

The one component I'm really unhappy with is the a/c high pressure switch. It's rated at something like 350 PSI, a bit high for my liking, might try a klixon type snap on temp switch on the condenser outlet. A 145° close, 135° open would help keep the high pressure below 250 psi. A 150/135 is easy to find, but would let the pressures rise to over 260 psi before closing.

#4

Thanks for the kind words.

The fan assembly is the first thing I've shoved under the hood that clearly does not look like it is OEM. Figured the least I could do was make it look half way presentable!

I was tempted to build a mold and make the shroud out of fiber glass. Could have added an OEM look but for a one-off build, just could not see my way down that path.

Oh, and I double checked, I used 80 amp relays, not 70. NO way are those fans going to burn up the relays!

The fan assembly is the first thing I've shoved under the hood that clearly does not look like it is OEM. Figured the least I could do was make it look half way presentable!

I was tempted to build a mold and make the shroud out of fiber glass. Could have added an OEM look but for a one-off build, just could not see my way down that path.

Oh, and I double checked, I used 80 amp relays, not 70. NO way are those fans going to burn up the relays!

#6

My complaint with it has largely been the noise it makes and how heavy it is.

Might be a pipe dream but I'm hoping to see a modest improvement in fuel economy but even without that, the engine seems more responsive and the noise from under the hood, particularly on acceleration, is greatly reduced.

For sure, all that noise is wasted energy. I've always though the later nylon fans were more efficient and are a lot quieter, but those have a reputation of cracking and shedding blades so by eliminating the monster of a fan blade and making the fan assembly an easy in-easy out, should make some maintenance items less arduous.

Thread

Thread Starter

Forum

Replies

Last Post

njdriver04

SOHC - 2.3L & 2.5L Lima Engines

6

01-13-2012 01:34 PM

Idrivebadassfords

8-Cylinder Tech

12

08-14-2011 05:23 AM

winks

General Technical & Electrical

10

10-10-2007 08:08 AM

n3elz

2.9L & 3.0L V6 Tech

38

11-01-2005 04:34 PM