DTCs P0171, P0174, P0304, & P0305

#1

DTCs P0171, P0174, P0304, & P0305

2001 XLT 4.0 4wd

So just got this truck and had to take it to Auto Zone and get codes pulled for CEL. The lady working at the counter seemed pretty confident in saying "swap the MAF I've seen this before with those sets of codes together". I do not want to spend $95 without properly diagnosing it first. Drove the truck last night for about two hours on the highway headed home. Realized the fuel consumption seems excessive. It does not idle rough, will not lag or hesitate under load, runs through the gears smooth, and not stalling or anything. Climbed up to 70 mph no issues. The plug wires look like they've been changed very recently, which is funny coz the diagnostic sheet from AutoZone says "change plugs and wires" but for a truck with 186k miles those wires I'm looking at are definitely fairly new. Code P0304 AND P0305 indicate misfire at cylinder 4 & 5. I'm sure you guys have dealt with P0171 and P0174 before. I've been reading since its two misfires perhaps the coil pack could be faulty. As I stated before, the truck idles fine. Only thing I noticed was excessive fuel consumption, almost half a tank gone just driving 100 miles at about 65-70mph all on the highway. Then again thats still about 15mpg so I could be just exaggerating. What do you guys suggest? Since it idles fine, should I check for vacuum leaks and inspect as many hoses as I can? I read I should test the EGR valve as well and inspect the hoses on that too. I'm thinking I'll clean out the MAF with some MAF spray cleaner and see if it does anything as well. Snow hasn't started but I'd like to get all these tinks addressed so I'm ready for the winter.

So just got this truck and had to take it to Auto Zone and get codes pulled for CEL. The lady working at the counter seemed pretty confident in saying "swap the MAF I've seen this before with those sets of codes together". I do not want to spend $95 without properly diagnosing it first. Drove the truck last night for about two hours on the highway headed home. Realized the fuel consumption seems excessive. It does not idle rough, will not lag or hesitate under load, runs through the gears smooth, and not stalling or anything. Climbed up to 70 mph no issues. The plug wires look like they've been changed very recently, which is funny coz the diagnostic sheet from AutoZone says "change plugs and wires" but for a truck with 186k miles those wires I'm looking at are definitely fairly new. Code P0304 AND P0305 indicate misfire at cylinder 4 & 5. I'm sure you guys have dealt with P0171 and P0174 before. I've been reading since its two misfires perhaps the coil pack could be faulty. As I stated before, the truck idles fine. Only thing I noticed was excessive fuel consumption, almost half a tank gone just driving 100 miles at about 65-70mph all on the highway. Then again thats still about 15mpg so I could be just exaggerating. What do you guys suggest? Since it idles fine, should I check for vacuum leaks and inspect as many hoses as I can? I read I should test the EGR valve as well and inspect the hoses on that too. I'm thinking I'll clean out the MAF with some MAF spray cleaner and see if it does anything as well. Snow hasn't started but I'd like to get all these tinks addressed so I'm ready for the winter.

Last edited by gary_lavagnino; 11-05-2017 at 06:01 PM. Reason: Add engine info

#2

Welcome to the forum

Best to include year of vehicle and engine size in posts

Yes, this is the 4.0l forum but people have posted 3.0l questions here

And code definitions if you have already looked them up

P0171 System too Lean (Bank 1) Passenger side

P0174 System too Lean (Bank 2) Drivers side

P0304 Cylinder 4 Misfire Detected

P0305 Cylinder 5 Misfire Detected

Short version suggestions, since you have no history on the vehicle, would be to replace both upstream O2 sensors, they need to be replaced every 100k anyway, old O2s give "false Lean" so MPG drops because of false Lean code

You should Clean MAF sensor, not replace it, needs to be cleaned every few years

After engine is fully warmed up, let it idle and unplug the 2 wire connector on IAC Valve

Engine RPMs should drop to 500 or engine may even stall, either is good it means no vacuum leak.

If idle stays high then you DO have a vacuum leak somewhere

Long version

First, Lean doesn't actually mean engine is running lean, Lean or Rich codes mean computer is having to add more fuel(lean) or less fuel(rich) than it calculated

Computer "knows" it is running a 4 liter engine, in this case, so it "knows" how much air a 4 liter engine will use at any rpm and any throttle position.

And it "knows" it needs a 14.7:1 air to gasoline ratio, this is a weight ratio, 14.7grams of air to 1 gram of gasoline

So before anything happens computer has base calculations done, takes a few milliseconds.

It then uses MAF(mass air flow) sensor data to fine tune the "Weight" of the air coming in and its temperature.

It adjusts ratio for "weight" of air, high altitude, low altitude, humid, dry.

Gasoline weight doesn't change much

Computer then adds calculated fuel to intake via injectors

It then gets Oxygen levels in exhaust from O2 sensors, one on each Bank

If O2 reports too much oxygen(lean) then computer adds more fuel to that bank

If too little oxygen(rich) then computer adds less fuel to that bank

If fuel calculation is off by more than 15-20% then computer sets a code letting driver know there is a problem.

Lean code means computer is adding more fuel than calculated

Since Both banks show Lean code MAF sensor could indeed be the problem as it would effect both banks of engine.

Or an upper intake air leak, so all air is not coming in through MAF sensor

But on unknown history both O2s could be in question, and O2s fail Lean, so engine runs Richer than it should i.e. lower MPG

Can also cause Rich misfires

A misfire means NO OXYGEN was burned in that cylinder, so that oxygen is dumped into exhaust and O2 sensor "see" it, and thats Lean, too much oxygen, so computer must add more fuel, and can set Lean code.

But 4 and 5 are on the same bank so that wouldn't account for Lean on Bank 1

Coil pack would be a long shot

There are 3 coils in the coil pack

[3 4]

[2 6]

[1 5]

front

4 and 5 do not share a coil in the pack, so would be a long shot for 2 coil in the pack to fail at the same time

4 and 5 spark plugs could be failing, or worse case, head gasket failure between cylinders, this doesn't cause overheating or any other problems besides the misfires

Best to include year of vehicle and engine size in posts

Yes, this is the 4.0l forum but people have posted 3.0l questions here

And code definitions if you have already looked them up

P0171 System too Lean (Bank 1) Passenger side

P0174 System too Lean (Bank 2) Drivers side

P0304 Cylinder 4 Misfire Detected

P0305 Cylinder 5 Misfire Detected

Short version suggestions, since you have no history on the vehicle, would be to replace both upstream O2 sensors, they need to be replaced every 100k anyway, old O2s give "false Lean" so MPG drops because of false Lean code

You should Clean MAF sensor, not replace it, needs to be cleaned every few years

After engine is fully warmed up, let it idle and unplug the 2 wire connector on IAC Valve

Engine RPMs should drop to 500 or engine may even stall, either is good it means no vacuum leak.

If idle stays high then you DO have a vacuum leak somewhere

Long version

First, Lean doesn't actually mean engine is running lean, Lean or Rich codes mean computer is having to add more fuel(lean) or less fuel(rich) than it calculated

Computer "knows" it is running a 4 liter engine, in this case, so it "knows" how much air a 4 liter engine will use at any rpm and any throttle position.

And it "knows" it needs a 14.7:1 air to gasoline ratio, this is a weight ratio, 14.7grams of air to 1 gram of gasoline

So before anything happens computer has base calculations done, takes a few milliseconds.

It then uses MAF(mass air flow) sensor data to fine tune the "Weight" of the air coming in and its temperature.

It adjusts ratio for "weight" of air, high altitude, low altitude, humid, dry.

Gasoline weight doesn't change much

Computer then adds calculated fuel to intake via injectors

It then gets Oxygen levels in exhaust from O2 sensors, one on each Bank

If O2 reports too much oxygen(lean) then computer adds more fuel to that bank

If too little oxygen(rich) then computer adds less fuel to that bank

If fuel calculation is off by more than 15-20% then computer sets a code letting driver know there is a problem.

Lean code means computer is adding more fuel than calculated

Since Both banks show Lean code MAF sensor could indeed be the problem as it would effect both banks of engine.

Or an upper intake air leak, so all air is not coming in through MAF sensor

But on unknown history both O2s could be in question, and O2s fail Lean, so engine runs Richer than it should i.e. lower MPG

Can also cause Rich misfires

A misfire means NO OXYGEN was burned in that cylinder, so that oxygen is dumped into exhaust and O2 sensor "see" it, and thats Lean, too much oxygen, so computer must add more fuel, and can set Lean code.

But 4 and 5 are on the same bank so that wouldn't account for Lean on Bank 1

Coil pack would be a long shot

There are 3 coils in the coil pack

[3 4]

[2 6]

[1 5]

front

4 and 5 do not share a coil in the pack, so would be a long shot for 2 coil in the pack to fail at the same time

4 and 5 spark plugs could be failing, or worse case, head gasket failure between cylinders, this doesn't cause overheating or any other problems besides the misfires

#3

Welcome to the forum

Best to include year of vehicle and engine size in posts

Yes, this is the 4.0l forum but people have posted 3.0l questions here

And code definitions if you have already looked them up

P0171 System too Lean (Bank 1) Passenger side

P0174 System too Lean (Bank 2) Drivers side

P0304 Cylinder 4 Misfire Detected

P0305 Cylinder 5 Misfire Detected

Short version suggestions, since you have no history on the vehicle, would be to replace both upstream O2 sensors, they need to be replaced every 100k anyway, old O2s give "false Lean" so MPG drops because of false Lean code

You should Clean MAF sensor, not replace it, needs to be cleaned every few years

After engine is fully warmed up, let it idle and unplug the 2 wire connector on IAC Valve

Engine RPMs should drop to 500 or engine may even stall, either is good it means no vacuum leak.

If idle stays high then you DO have a vacuum leak somewhere

Long version

First, Lean doesn't actually mean engine is running lean, Lean or Rich codes mean computer is having to add more fuel(lean) or less fuel(rich) than it calculated

Computer "knows" it is running a 4 liter engine, in this case, so it "knows" how much air a 4 liter engine will use at any rpm and any throttle position.

And it "knows" it needs a 14.7:1 air to gasoline ratio, this is a weight ratio, 14.7grams of air to 1 gram of gasoline

So before anything happens computer has base calculations done, takes a few milliseconds.

It then uses MAF(mass air flow) sensor data to fine tune the "Weight" of the air coming in and its temperature.

It adjusts ratio for "weight" of air, high altitude, low altitude, humid, dry.

Gasoline weight doesn't change much

Computer then adds calculated fuel to intake via injectors

It then gets Oxygen levels in exhaust from O2 sensors, one on each Bank

If O2 reports too much oxygen(lean) then computer adds more fuel to that bank

If too little oxygen(rich) then computer adds less fuel to that bank

If fuel calculation is off by more than 15-20% then computer sets a code letting driver know there is a problem.

Lean code means computer is adding more fuel than calculated

Since Both banks show Lean code MAF sensor could indeed be the problem as it would effect both banks of engine.

Or an upper intake air leak, so all air is not coming in through MAF sensor

But on unknown history both O2s could be in question, and O2s fail Lean, so engine runs Richer than it should i.e. lower MPG

Can also cause Rich misfires

A misfire means NO OXYGEN was burned in that cylinder, so that oxygen is dumped into exhaust and O2 sensor "see" it, and thats Lean, too much oxygen, so computer must add more fuel, and can set Lean code.

But 4 and 5 are on the same bank so that wouldn't account for Lean on Bank 1

Coil pack would be a long shot

There are 3 coils in the coil pack

[3 4]

[2 6]

[1 5]

front

4 and 5 do not share a coil in the pack, so would be a long shot for 2 coil in the pack to fail at the same time

4 and 5 spark plugs could be failing, or worse case, head gasket failure between cylinders, this doesn't cause overheating or any other problems besides the misfires

Best to include year of vehicle and engine size in posts

Yes, this is the 4.0l forum but people have posted 3.0l questions here

And code definitions if you have already looked them up

P0171 System too Lean (Bank 1) Passenger side

P0174 System too Lean (Bank 2) Drivers side

P0304 Cylinder 4 Misfire Detected

P0305 Cylinder 5 Misfire Detected

Short version suggestions, since you have no history on the vehicle, would be to replace both upstream O2 sensors, they need to be replaced every 100k anyway, old O2s give "false Lean" so MPG drops because of false Lean code

You should Clean MAF sensor, not replace it, needs to be cleaned every few years

After engine is fully warmed up, let it idle and unplug the 2 wire connector on IAC Valve

Engine RPMs should drop to 500 or engine may even stall, either is good it means no vacuum leak.

If idle stays high then you DO have a vacuum leak somewhere

Long version

First, Lean doesn't actually mean engine is running lean, Lean or Rich codes mean computer is having to add more fuel(lean) or less fuel(rich) than it calculated

Computer "knows" it is running a 4 liter engine, in this case, so it "knows" how much air a 4 liter engine will use at any rpm and any throttle position.

And it "knows" it needs a 14.7:1 air to gasoline ratio, this is a weight ratio, 14.7grams of air to 1 gram of gasoline

So before anything happens computer has base calculations done, takes a few milliseconds.

It then uses MAF(mass air flow) sensor data to fine tune the "Weight" of the air coming in and its temperature.

It adjusts ratio for "weight" of air, high altitude, low altitude, humid, dry.

Gasoline weight doesn't change much

Computer then adds calculated fuel to intake via injectors

It then gets Oxygen levels in exhaust from O2 sensors, one on each Bank

If O2 reports too much oxygen(lean) then computer adds more fuel to that bank

If too little oxygen(rich) then computer adds less fuel to that bank

If fuel calculation is off by more than 15-20% then computer sets a code letting driver know there is a problem.

Lean code means computer is adding more fuel than calculated

Since Both banks show Lean code MAF sensor could indeed be the problem as it would effect both banks of engine.

Or an upper intake air leak, so all air is not coming in through MAF sensor

But on unknown history both O2s could be in question, and O2s fail Lean, so engine runs Richer than it should i.e. lower MPG

Can also cause Rich misfires

A misfire means NO OXYGEN was burned in that cylinder, so that oxygen is dumped into exhaust and O2 sensor "see" it, and thats Lean, too much oxygen, so computer must add more fuel, and can set Lean code.

But 4 and 5 are on the same bank so that wouldn't account for Lean on Bank 1

Coil pack would be a long shot

There are 3 coils in the coil pack

[3 4]

[2 6]

[1 5]

front

4 and 5 do not share a coil in the pack, so would be a long shot for 2 coil in the pack to fail at the same time

4 and 5 spark plugs could be failing, or worse case, head gasket failure between cylinders, this doesn't cause overheating or any other problems besides the misfires

#4

Coil packs rarely fail, not never, but really the very last thing in the spark system to check

You can check them with an OHM Meter.

I would pull out all spark plugs but look closely at 4 and 5 plugs to see what the tips tell you about conditions inside those cylinders, compared to the other non-misfiring cylinders

Google: Spark plug tips chart

Just use regular copper spark plugs as replacements for now

Never use single platinum with Coil Packs, double platinum or regular copper only

4.0l likes motorcraft or autolite spark plugs, tends to "eat" other brands

4.0l also uses a wide gap, 0.054

Vacuum leak wouldn't explain excess fuel use

The computer is getting wrong air flow info from MAF because extra air is coming in, so it would set Lean codes because of that.

But MPG would remain the same since O2 sensors are reporting good oxygen levels in exhaust.

Lean or Rich codes are strictly calculation errors and wouldn't change MPG one bit

You also don't mention the year of the 4.0l??

1997 and earlier use Fuel Pressure regulators, they could leak and fuel would be sucked into engine causing excessive fuel use

If odometer shows more than 100k miles then replacing O2s is not "just because", they need to be replaced, just like oil needs to be changed, and fuel filters need to be changed, part of general maintenance

If vehicle is 1995 or later then it will have a 3rd O2 behind Cats, it doesn't need to be changed, maybe after 250k miles

There is a quick and simple test for leaking injectors, a cause of lower MPG

After engine is warmed up, shut it off

Press gas pedal down to the floor and hold it down all the way, this will TURN OFF all fuel injectors while cranking engine, it is called "Clear Flooded Engine" routine, all fuel injection computer have this

Cycle key on and off 3 times, turns on fuel pump 3 times to get max pressure at engine

With gas pedal held down all the way crank the engine, it should NOT start, it should NOT fire at all

If it does then you have a leaking injector

You can ID which injector(s) might be leaking after engine cools down, using same test above, but unplug the coil pack so no spark

Crank engine with gas pedal down

Then pull out the spark plugs

WET tip plug has the leaky injector

You can check them with an OHM Meter.

I would pull out all spark plugs but look closely at 4 and 5 plugs to see what the tips tell you about conditions inside those cylinders, compared to the other non-misfiring cylinders

Google: Spark plug tips chart

Just use regular copper spark plugs as replacements for now

Never use single platinum with Coil Packs, double platinum or regular copper only

4.0l likes motorcraft or autolite spark plugs, tends to "eat" other brands

4.0l also uses a wide gap, 0.054

Vacuum leak wouldn't explain excess fuel use

The computer is getting wrong air flow info from MAF because extra air is coming in, so it would set Lean codes because of that.

But MPG would remain the same since O2 sensors are reporting good oxygen levels in exhaust.

Lean or Rich codes are strictly calculation errors and wouldn't change MPG one bit

You also don't mention the year of the 4.0l??

1997 and earlier use Fuel Pressure regulators, they could leak and fuel would be sucked into engine causing excessive fuel use

If odometer shows more than 100k miles then replacing O2s is not "just because", they need to be replaced, just like oil needs to be changed, and fuel filters need to be changed, part of general maintenance

If vehicle is 1995 or later then it will have a 3rd O2 behind Cats, it doesn't need to be changed, maybe after 250k miles

There is a quick and simple test for leaking injectors, a cause of lower MPG

After engine is warmed up, shut it off

Press gas pedal down to the floor and hold it down all the way, this will TURN OFF all fuel injectors while cranking engine, it is called "Clear Flooded Engine" routine, all fuel injection computer have this

Cycle key on and off 3 times, turns on fuel pump 3 times to get max pressure at engine

With gas pedal held down all the way crank the engine, it should NOT start, it should NOT fire at all

If it does then you have a leaking injector

You can ID which injector(s) might be leaking after engine cools down, using same test above, but unplug the coil pack so no spark

Crank engine with gas pedal down

Then pull out the spark plugs

WET tip plug has the leaky injector

Last edited by RonD; 11-06-2017 at 10:09 AM.

#5

Coil packs rarely fail, not never, but really the very last thing in the spark system to check

You can check them with an OHM Meter.

I would pull out all spark plugs but look closely at 4 and 5 plugs to see what the tips tell you about conditions inside those cylinders, compared to the other non-misfiring cylinders

Google: Spark plug tips chart

Just use regular copper spark plugs as replacements for now

Never use single platinum with Coil Packs, double platinum or regular copper only

4.0l likes motorcraft or autolite spark plugs, tends to "eat" other brands

4.0l also uses a wide gap, 0.054

Vacuum leak wouldn't explain excess fuel use

The computer is getting wrong air flow info from MAF because extra air is coming in, so it would set Lean codes because of that.

But MPG would remain the same since O2 sensors are reporting good oxygen levels in exhaust.

Lean or Rich codes are strictly calculation errors and wouldn't change MPG one bit

You also don't mention the year of the 4.0l??

1997 and earlier use Fuel Pressure regulators, they could leak and fuel would be sucked into engine causing excessive fuel use

If odometer shows more than 100k miles then replacing O2s is not "just because", they need to be replaced, just like oil needs to be changed, and fuel filters need to be changed, part of general maintenance

If vehicle is 1995 or later then it will have a 3rd O2 behind Cats, it doesn't need to be changed, maybe after 250k miles

There is a quick and simple test for leaking injectors, a cause of lower MPG

After engine is warmed up, shut it off

Press gas pedal down to the floor and hold it down all the way, this will TURN OFF all fuel injectors while cranking engine, it is called "Clear Flooded Engine" routine, all fuel injection computer have this

Cycle key on and off 3 times, turns on fuel pump 3 times to get max pressure at engine

With gas pedal held down all the way crank the engine, it should NOT start, it should NOT fire at all

If it does then you have a leaking injector

You can ID which injector(s) might be leaking after engine cools down, using same test above, but unplug the coil pack so no spark

Crank engine with gas pedal down

Then pull out the spark plugs

WET tip plug has the leaky injector

You can check them with an OHM Meter.

I would pull out all spark plugs but look closely at 4 and 5 plugs to see what the tips tell you about conditions inside those cylinders, compared to the other non-misfiring cylinders

Google: Spark plug tips chart

Just use regular copper spark plugs as replacements for now

Never use single platinum with Coil Packs, double platinum or regular copper only

4.0l likes motorcraft or autolite spark plugs, tends to "eat" other brands

4.0l also uses a wide gap, 0.054

Vacuum leak wouldn't explain excess fuel use

The computer is getting wrong air flow info from MAF because extra air is coming in, so it would set Lean codes because of that.

But MPG would remain the same since O2 sensors are reporting good oxygen levels in exhaust.

Lean or Rich codes are strictly calculation errors and wouldn't change MPG one bit

You also don't mention the year of the 4.0l??

1997 and earlier use Fuel Pressure regulators, they could leak and fuel would be sucked into engine causing excessive fuel use

If odometer shows more than 100k miles then replacing O2s is not "just because", they need to be replaced, just like oil needs to be changed, and fuel filters need to be changed, part of general maintenance

If vehicle is 1995 or later then it will have a 3rd O2 behind Cats, it doesn't need to be changed, maybe after 250k miles

There is a quick and simple test for leaking injectors, a cause of lower MPG

After engine is warmed up, shut it off

Press gas pedal down to the floor and hold it down all the way, this will TURN OFF all fuel injectors while cranking engine, it is called "Clear Flooded Engine" routine, all fuel injection computer have this

Cycle key on and off 3 times, turns on fuel pump 3 times to get max pressure at engine

With gas pedal held down all the way crank the engine, it should NOT start, it should NOT fire at all

If it does then you have a leaking injector

You can ID which injector(s) might be leaking after engine cools down, using same test above, but unplug the coil pack so no spark

Crank engine with gas pedal down

Then pull out the spark plugs

WET tip plug has the leaky injector

#7

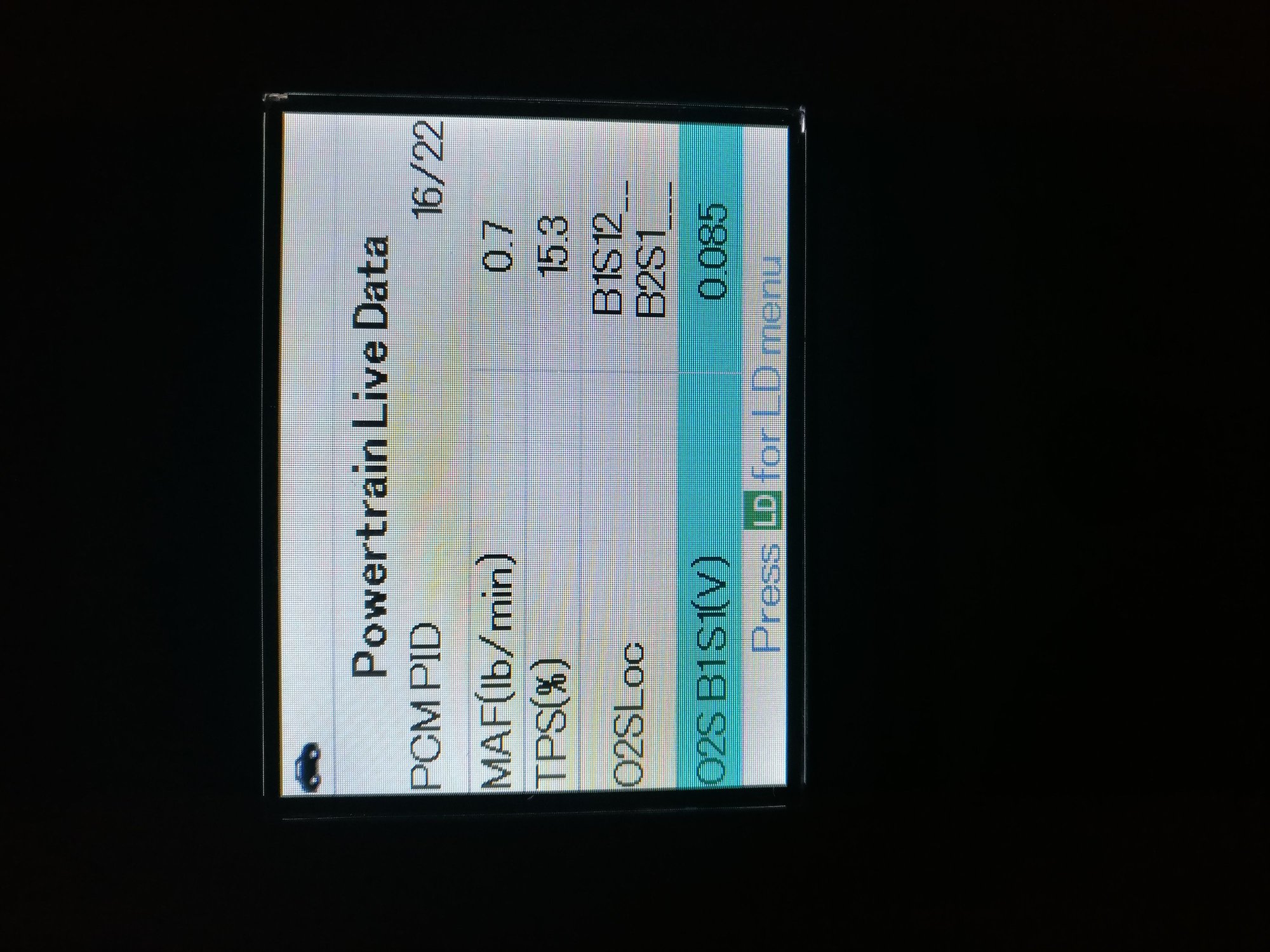

Sort of good news. After doing all the tips you gave me and cleaning the MAF, I went out and got myself a nice scanner with Live Data. I cleared the codes and the P0171 & P0174 are gone. Not even 5 minutes later, P0304 & P0305 came back. The weird smell is coming out from the exhaust and I suspect like you've been saying all along, plugs on cylinder 4&5 have gone bad.

#8

#10

Ron, turns out I was wrong and its a 3.0 not a 4.0 engine. Anyways, now I'm having a no start issue. I took out to drive it to the auto skills center because I am in the military and wanted to get working on the plugs. Had an issue so couldn't get started and had to leave. As I'm TRYING to leave, go to crank it and no start not even a click. The staff had a jump starter and it fired up. Figured I'd replace the battery since it looked pretty beat up anyways. So got the new one, replaced the negative battery cable terminal while I was in there (all lights working, pretty clean terminal replacement if I do say so myself) go to start and STILL not even a damn CLICK! This is is starting to make me scratch my head. HELP PLEASE IF YOU CAN

#11

If turning key to START doesn't cause starter motor to work then:

If automatic shift to Neutral and try again

If Manual push clutch in a few times and try again

There is a Neutral safety switch, different switch depending on transmission

It prevents key from passing power to turn on starter motor, no click

2001 will also have PATS(passive anti-theft)

On the dash there will be a Theft Light, flashes every 3 seconds or so

If you turn on the key and it flashes Rapidly, it means Key you are using didn't pass PATS and starter relay is off, no click

OR.............starter motor could be dead, it just happens, no warning, just no start one day

Jump 12v to "S" post on starter motor, it has the Yellow/blue stripe wire on it now, 12volt to that terminal will get starter motor to turn engine IF motor is OK

EDIT:

Overlooked one more thing, fuse 24 in cab fuse box, 7.5amp, if it blows no starter motor, no click

If automatic shift to Neutral and try again

If Manual push clutch in a few times and try again

There is a Neutral safety switch, different switch depending on transmission

It prevents key from passing power to turn on starter motor, no click

2001 will also have PATS(passive anti-theft)

On the dash there will be a Theft Light, flashes every 3 seconds or so

If you turn on the key and it flashes Rapidly, it means Key you are using didn't pass PATS and starter relay is off, no click

OR.............starter motor could be dead, it just happens, no warning, just no start one day

Jump 12v to "S" post on starter motor, it has the Yellow/blue stripe wire on it now, 12volt to that terminal will get starter motor to turn engine IF motor is OK

EDIT:

Overlooked one more thing, fuse 24 in cab fuse box, 7.5amp, if it blows no starter motor, no click

Last edited by RonD; 11-08-2017 at 07:40 PM.

#12

If turning key to START doesn't cause starter motor to work then:

If automatic shift to Neutral and try again

If Manual push clutch in a few times and try again

There is a Neutral safety switch, different switch depending on transmission

It prevents key from passing power to turn on starter motor, no click

2001 will also have PATS(passive anti-theft)

On the dash there will be a Theft Light, flashes every 3 seconds or so

If you turn on the key and it flashes Rapidly, it means Key you are using didn't pass PATS and starter relay is off, no click

OR.............starter motor could be dead, it just happens, no warning, just no start one day

Jump 12v to "S" post on starter motor, it has the Yellow/blue stripe wire on it now, 12volt to that terminal will get starter motor to turn engine IF motor is OK

EDIT:

Overlooked one more thing, fuse 24 in cab fuse box, 7.5amp, if it blows no starter motor, no click

If automatic shift to Neutral and try again

If Manual push clutch in a few times and try again

There is a Neutral safety switch, different switch depending on transmission

It prevents key from passing power to turn on starter motor, no click

2001 will also have PATS(passive anti-theft)

On the dash there will be a Theft Light, flashes every 3 seconds or so

If you turn on the key and it flashes Rapidly, it means Key you are using didn't pass PATS and starter relay is off, no click

OR.............starter motor could be dead, it just happens, no warning, just no start one day

Jump 12v to "S" post on starter motor, it has the Yellow/blue stripe wire on it now, 12volt to that terminal will get starter motor to turn engine IF motor is OK

EDIT:

Overlooked one more thing, fuse 24 in cab fuse box, 7.5amp, if it blows no starter motor, no click

*Completely forgot to test the neutral saftey switch by attempting to start it from neutral. Will try that tomorrow. Almost hoping that's out, cheaper than the starter and easy access.

#13

Spark plug looks good, light tan is what you want to see

If Motorcraft is not available then Autolite is next in line

If you have an automatic then yes, try Neutral

Ford truck column shifters are known to loosen up, and may not go into Park far enough to set Neutral switch

Starter motor can be wiggled out, tight squeeze but doable

First test it by running 12v jumper to "S" contact on the starter

Image here of starter motor: https://static.cargurus.com/images/s...1600x1200.jpeg

Generic, they are all the same

Larger post on the top is where Positive battery cable connects

Smaller post on the left is the "S" post

When S post gets 12volts(usually from Key) it activates the internal relay(solenoid) which connects that larger post at the top to the large post under it, and that sends Battery Power to starter motor.

You could just use short jumper from upper large post to smaller post on the left, starter motor should "click" then activate, if not then motor is dead

If Motorcraft is not available then Autolite is next in line

If you have an automatic then yes, try Neutral

Ford truck column shifters are known to loosen up, and may not go into Park far enough to set Neutral switch

Starter motor can be wiggled out, tight squeeze but doable

First test it by running 12v jumper to "S" contact on the starter

Image here of starter motor: https://static.cargurus.com/images/s...1600x1200.jpeg

Generic, they are all the same

Larger post on the top is where Positive battery cable connects

Smaller post on the left is the "S" post

When S post gets 12volts(usually from Key) it activates the internal relay(solenoid) which connects that larger post at the top to the large post under it, and that sends Battery Power to starter motor.

You could just use short jumper from upper large post to smaller post on the left, starter motor should "click" then activate, if not then motor is dead

#14

Spark plug looks good, light tan is what you want to see

If Motorcraft is not available then Autolite is next in line

If you have an automatic then yes, try Neutral

Ford truck column shifters are known to loosen up, and may not go into Park far enough to set Neutral switch

Starter motor can be wiggled out, tight squeeze but doable

First test it by running 12v jumper to "S" contact on the starter

Image here of starter motor: https://static.cargurus.com/images/s...1600x1200.jpeg

Generic, they are all the same

Larger post on the top is where Positive battery cable connects

Smaller post on the left is the "S" post

When S post gets 12volts(usually from Key) it activates the internal relay(solenoid) which connects that larger post at the top to the large post under it, and that sends Battery Power to starter motor.

You could just use short jumper from upper large post to smaller post on the left, starter motor should "click" then activate, if not then motor is dead

If Motorcraft is not available then Autolite is next in line

If you have an automatic then yes, try Neutral

Ford truck column shifters are known to loosen up, and may not go into Park far enough to set Neutral switch

Starter motor can be wiggled out, tight squeeze but doable

First test it by running 12v jumper to "S" contact on the starter

Image here of starter motor: https://static.cargurus.com/images/s...1600x1200.jpeg

Generic, they are all the same

Larger post on the top is where Positive battery cable connects

Smaller post on the left is the "S" post

When S post gets 12volts(usually from Key) it activates the internal relay(solenoid) which connects that larger post at the top to the large post under it, and that sends Battery Power to starter motor.

You could just use short jumper from upper large post to smaller post on the left, starter motor should "click" then activate, if not then motor is dead

#15

I would get a longer vacuum hose for use as a stethoscope, listen to each fuel injector

Ford fuel injectors can be quite loud, and they make exactly the same noise as a lifter tick

I don't think pouring or spraying ANY liquid into a running engine is a "sane" idea

Very little upside and blown engine is the downside, so IMO, not really a good idea in any way shape or form.

Seafoam in the gas tank is good

Burning gasoline(H) with air(O) produces H2O(water) as a by product, this is why exhaust systems rust from the inside out and why water drips from tail pipes.

When you shut off an engine the water in the exhaust system condenses inside pipes, cats and mufflers.

When you restart all that water gets hot again and you will see it as white smoke until exhaust system heats up fully.

In humid weather there is even more water in the exhaust

And depending on outside temp the white smoke can get quite thick as it condenses again in cold air

Ford fuel injectors can be quite loud, and they make exactly the same noise as a lifter tick

I don't think pouring or spraying ANY liquid into a running engine is a "sane" idea

Very little upside and blown engine is the downside, so IMO, not really a good idea in any way shape or form.

Seafoam in the gas tank is good

Burning gasoline(H) with air(O) produces H2O(water) as a by product, this is why exhaust systems rust from the inside out and why water drips from tail pipes.

When you shut off an engine the water in the exhaust system condenses inside pipes, cats and mufflers.

When you restart all that water gets hot again and you will see it as white smoke until exhaust system heats up fully.

In humid weather there is even more water in the exhaust

And depending on outside temp the white smoke can get quite thick as it condenses again in cold air

#16

I would get a longer vacuum hose for use as a stethoscope, listen to each fuel injector

Ford fuel injectors can be quite loud, and they make exactly the same noise as a lifter tick

I don't think pouring or spraying ANY liquid into a running engine is a "sane" idea

Very little upside and blown engine is the downside, so IMO, not really a good idea in any way shape or form.

Seafoam in the gas tank is good

Burning gasoline(H) with air(O) produces H2O(water) as a by product, this is why exhaust systems rust from the inside out and why water drips from tail pipes.

When you shut off an engine the water in the exhaust system condenses inside pipes, cats and mufflers.

When you restart all that water gets hot again and you will see it as white smoke until exhaust system heats up fully.

In humid weather there is even more water in the exhaust

And depending on outside temp the white smoke can get quite thick as it condenses again in cold air

Ford fuel injectors can be quite loud, and they make exactly the same noise as a lifter tick

I don't think pouring or spraying ANY liquid into a running engine is a "sane" idea

Very little upside and blown engine is the downside, so IMO, not really a good idea in any way shape or form.

Seafoam in the gas tank is good

Burning gasoline(H) with air(O) produces H2O(water) as a by product, this is why exhaust systems rust from the inside out and why water drips from tail pipes.

When you shut off an engine the water in the exhaust system condenses inside pipes, cats and mufflers.

When you restart all that water gets hot again and you will see it as white smoke until exhaust system heats up fully.

In humid weather there is even more water in the exhaust

And depending on outside temp the white smoke can get quite thick as it condenses again in cold air

#17

P0174 is Lean on Bank 2, drivers side, cylinders 4, 5 and 6

Lean is misleading unless you know how computer "thinks", it doesn't, lol, vending machine from the '60's is smarter than any vehicle "computer", it is actually a calculator for on the fly air/fuel mix fuel injection.

After engine is warmed up the O2 sensors start to work, they are called "O2" sensors because they can ONLY SEE oxygen, not gasoline, OXYGEN

If a cylinder should misfire, then NO OXYGEN is burned up, so it will be dumped into exhaust and O2 sensors see TOO MUCH OXYGEN, which computer "thinks" is Lean

Computer responds to "lean" by added more gasoline to that Bank of the engine

If oxygen levels remain high it adds more gasoline, and more, it gets to a point(a limit) where it stops adding more gas and sets the Lean code P0174

So a misfire can set Lean code

After resetting computer or unplugging it from power, i.e. disconnect battery, it will take a few drive cycles for it to test all the emissions system again.

One drive cycle is coolant temp above 170deg and then restart with coolant temp below 130degF

So warm up and cool down, but it isn't quite that simple because computer doesn't start the test as soon as temp is 170deg, it might but might not either.

There can be NO CODES or no tests will be started, and it only runs one test at a time.

Catalyst test is last, and can take its sweet time, it won't start until other tests are complete and "passed" and there are no pending codes

Lean is misleading unless you know how computer "thinks", it doesn't, lol, vending machine from the '60's is smarter than any vehicle "computer", it is actually a calculator for on the fly air/fuel mix fuel injection.

After engine is warmed up the O2 sensors start to work, they are called "O2" sensors because they can ONLY SEE oxygen, not gasoline, OXYGEN

If a cylinder should misfire, then NO OXYGEN is burned up, so it will be dumped into exhaust and O2 sensors see TOO MUCH OXYGEN, which computer "thinks" is Lean

Computer responds to "lean" by added more gasoline to that Bank of the engine

If oxygen levels remain high it adds more gasoline, and more, it gets to a point(a limit) where it stops adding more gas and sets the Lean code P0174

So a misfire can set Lean code

After resetting computer or unplugging it from power, i.e. disconnect battery, it will take a few drive cycles for it to test all the emissions system again.

One drive cycle is coolant temp above 170deg and then restart with coolant temp below 130degF

So warm up and cool down, but it isn't quite that simple because computer doesn't start the test as soon as temp is 170deg, it might but might not either.

There can be NO CODES or no tests will be started, and it only runs one test at a time.

Catalyst test is last, and can take its sweet time, it won't start until other tests are complete and "passed" and there are no pending codes

#18

Replaced the PCV valve and fixed the breather hose going from the valve cover to the air inlet tube. Cleaned the MAF. Showed you the plug. Reconnected all the plug wires made sure they were tight on the plugs and the coil pack. C.E.L disappeared. Now, I hear a ticking at idle. Sounds like a lifter, definitely something in the valve train. More noticeable under load. I'll step on the gas and it gets louder but not where its rattling extremely loud. Do you recommend running seafoam spray through the throttle body? Noticed white smoke until it gets to operating temperature from exhaust. Hanger at the tail pipe has actually made its way through the tail pipe so gonna have to get a new piece welded on there. Started the truck it from neutral. Im thinking its the switch that wont let the column shifter put it all the way back into park unless i use some force. Starting fine now though it does sound like it still needs a starter too

A small leak can sound just like a noisy lifter, but they get louder and more pronounced under load.

Exhaust leaks can also set lean codes because not all the burned fuel is reaching the oxygen sensors.

You also said in post 5 that you're smelling a weird smell, sort of exhaust or oil. I'm assuming this is coming from the engine bay _ I think you do have some sort of an exhaust leak.

Had some friends may years ago that were driving themselves crazy trying to adjust the valve lash from a noisy lifter and it turned out to be a tiny leak in the gasket manifold.

Last edited by Jeff R 1; 11-12-2017 at 06:21 PM.

#19

Valve train noises don't get louder under load, look for a small exhaust leak.

A small leak can sound just like a noisy lifter, but they get louder and more pronounced under load.

Exhaust leaks can also set lean codes because not all the burned fuel is reaching the oxygen sensors.

You also said in post 5 that you're smelling a weird smell, sort of exhaust or oil. I'm assuming this is coming from the engine bay _ I think you do have some sort of an exhaust leak.

Had some friends may years ago that were driving themselves crazy trying to adjust the valve lash from a noisy lifter and it turned out to be a tiny leak in the gasket manifold.

A small leak can sound just like a noisy lifter, but they get louder and more pronounced under load.

Exhaust leaks can also set lean codes because not all the burned fuel is reaching the oxygen sensors.

You also said in post 5 that you're smelling a weird smell, sort of exhaust or oil. I'm assuming this is coming from the engine bay _ I think you do have some sort of an exhaust leak.

Had some friends may years ago that were driving themselves crazy trying to adjust the valve lash from a noisy lifter and it turned out to be a tiny leak in the gasket manifold.

#20

P0174 is Lean on Bank 2, drivers side, cylinders 4, 5 and 6

Lean is misleading unless you know how computer "thinks", it doesn't, lol, vending machine from the '60's is smarter than any vehicle "computer", it is actually a calculator for on the fly air/fuel mix fuel injection.

After engine is warmed up the O2 sensors start to work, they are called "O2" sensors because they can ONLY SEE oxygen, not gasoline, OXYGEN

If a cylinder should misfire, then NO OXYGEN is burned up, so it will be dumped into exhaust and O2 sensors see TOO MUCH OXYGEN, which computer "thinks" is Lean

Computer responds to "lean" by added more gasoline to that Bank of the engine

If oxygen levels remain high it adds more gasoline, and more, it gets to a point(a limit) where it stops adding more gas and sets the Lean code P0174

So a misfire can set Lean code

After resetting computer or unplugging it from power, i.e. disconnect battery, it will take a few drive cycles for it to test all the emissions system again.

One drive cycle is coolant temp above 170deg and then restart with coolant temp below 130degF

So warm up and cool down, but it isn't quite that simple because computer doesn't start the test as soon as temp is 170deg, it might but might not either.

There can be NO CODES or no tests will be started, and it only runs one test at a time.

Catalyst test is last, and can take its sweet time, it won't start until other tests are complete and "passed" and there are no pending codes

Lean is misleading unless you know how computer "thinks", it doesn't, lol, vending machine from the '60's is smarter than any vehicle "computer", it is actually a calculator for on the fly air/fuel mix fuel injection.

After engine is warmed up the O2 sensors start to work, they are called "O2" sensors because they can ONLY SEE oxygen, not gasoline, OXYGEN

If a cylinder should misfire, then NO OXYGEN is burned up, so it will be dumped into exhaust and O2 sensors see TOO MUCH OXYGEN, which computer "thinks" is Lean

Computer responds to "lean" by added more gasoline to that Bank of the engine

If oxygen levels remain high it adds more gasoline, and more, it gets to a point(a limit) where it stops adding more gas and sets the Lean code P0174

So a misfire can set Lean code

After resetting computer or unplugging it from power, i.e. disconnect battery, it will take a few drive cycles for it to test all the emissions system again.

One drive cycle is coolant temp above 170deg and then restart with coolant temp below 130degF

So warm up and cool down, but it isn't quite that simple because computer doesn't start the test as soon as temp is 170deg, it might but might not either.

There can be NO CODES or no tests will be started, and it only runs one test at a time.

Catalyst test is last, and can take its sweet time, it won't start until other tests are complete and "passed" and there are no pending codes

#21

1998 and up Rangers ran 60-70psi fuel pressure when running, 45psi at lowest after shut down

1997 and earlier ran 30-40psi

So 68psi is fine for 2001

Not sure what system Ford was using in 2001 computer, but there was a fuel pump duty cycle on some years.

Computers main purpose is to calculate fuel use, air/fuel mix, on the fly

So computer knows exactly how much fuel/pressure is being taken from the fuel rail at any given moment.

And it knows how much fuel the Stock fuel pump can provide/pump, GPH(gallons per hour)

So it can cycle the fuel pump power off and on to maintain the 60-70psi pressure "on the fly"

If the fuel pump was out of spec, less GPH, or not coming back on each time, intermittent contact, then replacing the pump would be called for

1997 and earlier ran 30-40psi

So 68psi is fine for 2001

Not sure what system Ford was using in 2001 computer, but there was a fuel pump duty cycle on some years.

Computers main purpose is to calculate fuel use, air/fuel mix, on the fly

So computer knows exactly how much fuel/pressure is being taken from the fuel rail at any given moment.

And it knows how much fuel the Stock fuel pump can provide/pump, GPH(gallons per hour)

So it can cycle the fuel pump power off and on to maintain the 60-70psi pressure "on the fly"

If the fuel pump was out of spec, less GPH, or not coming back on each time, intermittent contact, then replacing the pump would be called for

#22

1998 and up Rangers ran 60-70psi fuel pressure when running, 45psi at lowest after shut down

1997 and earlier ran 30-40psi

So 68psi is fine for 2001

Not sure what system Ford was using in 2001 computer, but there was a fuel pump duty cycle on some years.

Computers main purpose is to calculate fuel use, air/fuel mix, on the fly

So computer knows exactly how much fuel/pressure is being taken from the fuel rail at any given moment.

And it knows how much fuel the Stock fuel pump can provide/pump, GPH(gallons per hour)

So it can cycle the fuel pump power off and on to maintain the 60-70psi pressure "on the fly"

If the fuel pump was out of spec, less GPH, or not coming back on each time, intermittent contact, then replacing the pump would be called for

1997 and earlier ran 30-40psi

So 68psi is fine for 2001

Not sure what system Ford was using in 2001 computer, but there was a fuel pump duty cycle on some years.

Computers main purpose is to calculate fuel use, air/fuel mix, on the fly

So computer knows exactly how much fuel/pressure is being taken from the fuel rail at any given moment.

And it knows how much fuel the Stock fuel pump can provide/pump, GPH(gallons per hour)

So it can cycle the fuel pump power off and on to maintain the 60-70psi pressure "on the fly"

If the fuel pump was out of spec, less GPH, or not coming back on each time, intermittent contact, then replacing the pump would be called for

#23

Thread

Thread Starter

Forum

Replies

Last Post

glreynol

4.0L OHV & SOHC V6 Tech

48

06-06-2021 01:05 PM

kadillak1019

SOHC - 2.3L & 2.5L Lima Engines

0

12-26-2012 05:24 PM

Jp7

General Technical & Electrical

3

11-03-2009 05:38 PM