Plugs fire but no pulse???

#1

Plugs fire but no pulse???

Hello All.

I am new to your forum and hope someone can help...

I have a 93 Ranger 3.0L v6...

It has the distributor and remote ignition module on the radiator support...

No crank or cam position sensor on this model...

I replaced both the TPS and ignition module with new...

Injector red wires are all hot with 12V with key on...

I traced each injector signal wire back to the junction blocks on the inner finder (DS) and all have continuity...

I used a test light and get no flash or pulse from the injector connectors..I know the light works because.It works on my F-150

If I add gas to the throttle body it fires up for a couple of seconds...Getting fire to the plugs...

Last thing I can think of is that the injector drivers could be fried in the ECM...

Is there a procedure showing or describing how to check the drivers in the ecm

I'm just about lost on where to go next...

Thank you, Steve

I am new to your forum and hope someone can help...

I have a 93 Ranger 3.0L v6...

It has the distributor and remote ignition module on the radiator support...

No crank or cam position sensor on this model...

I replaced both the TPS and ignition module with new...

Injector red wires are all hot with 12V with key on...

I traced each injector signal wire back to the junction blocks on the inner finder (DS) and all have continuity...

I used a test light and get no flash or pulse from the injector connectors..I know the light works because.It works on my F-150

If I add gas to the throttle body it fires up for a couple of seconds...Getting fire to the plugs...

Last thing I can think of is that the injector drivers could be fried in the ECM...

Is there a procedure showing or describing how to check the drivers in the ecm

I'm just about lost on where to go next...

Thank you, Steve

#2

Welcome to the forum

Yes, 3.0l Rangers used TFI spark system thru 1994, 1995 and up were distributorless with Crank and Cam sensors(also different computer)

Look here for TFI info: Ford EEC-IV/TFI-IV Electronic Engine Control Troubleshooting : The Ranger Station

TFI has a hall effect sensor inside distributor, it reads the distributor shaft motion to set a PIP(Profile Ignition Pick-up), this is the timing pulse

TFI Module uses the PIP for spark timing, AND sends this PIP to the computer so it knows engine RPM and can set injector timing.

Since the computer has more info than TFI, like throttle position, engine load, and air/fuel mix, the computer sends back "suggestions" for spark advance to the TFI module on the SPOUT(SPark OUT) wire

The TFI module does the well and centrifugal advance, the Computer does the "Vacuum" advance in essence

So no injector pulse could be no PIP from TFI but if engine starts by adding fuel then TFI has PIP for spark.

So PIP wire from TFI to computer?

Or Computer itself?

Here is the computer you have, EEC-IV: Ford EEC-IV

You fuel injection is called Batch Fire, on a V6 two injectors on one bank and one injector on the other will open at the same time, then alternate with the others, 2 and 1

So basically one step up from a carb, Batch Fire keeps lower intake full of air/fuel mix like a carb did.

Pop open your computer, in the above link you can see what it should look like, you see the 3 Blue Capacitors, those fail and leak, causing issue, cost less than $5 to replace them if you can solder

Yes, 3.0l Rangers used TFI spark system thru 1994, 1995 and up were distributorless with Crank and Cam sensors(also different computer)

Look here for TFI info: Ford EEC-IV/TFI-IV Electronic Engine Control Troubleshooting : The Ranger Station

TFI has a hall effect sensor inside distributor, it reads the distributor shaft motion to set a PIP(Profile Ignition Pick-up), this is the timing pulse

TFI Module uses the PIP for spark timing, AND sends this PIP to the computer so it knows engine RPM and can set injector timing.

Since the computer has more info than TFI, like throttle position, engine load, and air/fuel mix, the computer sends back "suggestions" for spark advance to the TFI module on the SPOUT(SPark OUT) wire

The TFI module does the well and centrifugal advance, the Computer does the "Vacuum" advance in essence

So no injector pulse could be no PIP from TFI but if engine starts by adding fuel then TFI has PIP for spark.

So PIP wire from TFI to computer?

Or Computer itself?

Here is the computer you have, EEC-IV: Ford EEC-IV

You fuel injection is called Batch Fire, on a V6 two injectors on one bank and one injector on the other will open at the same time, then alternate with the others, 2 and 1

So basically one step up from a carb, Batch Fire keeps lower intake full of air/fuel mix like a carb did.

Pop open your computer, in the above link you can see what it should look like, you see the 3 Blue Capacitors, those fail and leak, causing issue, cost less than $5 to replace them if you can solder

#3

This is my ECM...Slightly different than the link...

Only 2 caps in this one...I'll check them last...

As soon as it quits raining I'm going back out to trace the PIP (pink #36) and Spout wires (#56 gray/orange) and see if I get continuity...

ECM is disconnected...

I will check for 12V on wires 1, 37, and 57 key on...

Next will check for grounds on 20,40, and 60...

Last edited by Steve1234; 06-20-2018 at 01:08 PM.

#4

#5

Caps are fine, image here of ones that are not fine: Capacitor Repair: Ford A9L ECM « Moates Support

Connector off the ECM

Pins 58 and 59 are the grounds for the injectors, if Batch fire, both should have 12v with key on, Ford injectors are low ohm, so just pass voltage thru.

If you have Sequential fuel injection then pin 58 will be for injector at cylinder #1

Pin 59 is #2

Pin 39 is #3

Pin 35 is #4

Pin 15 is #5

Pin 12 is #6

All should have 12volt with key on

Connector off the ECM

Pins 58 and 59 are the grounds for the injectors, if Batch fire, both should have 12v with key on, Ford injectors are low ohm, so just pass voltage thru.

If you have Sequential fuel injection then pin 58 will be for injector at cylinder #1

Pin 59 is #2

Pin 39 is #3

Pin 35 is #4

Pin 15 is #5

Pin 12 is #6

All should have 12volt with key on

#6

I ran the grounds from the ECM connector to each injector connector...

Some are dead...I stripped the covering from the engine ECM harness...

There are 3 block connectors for 3 sets of wires from termination to ECM block...

I'll clean all the blocks with Carbon.tet and check each wire...Tomorrow...

Thank you Ron...

Some are dead...I stripped the covering from the engine ECM harness...

There are 3 block connectors for 3 sets of wires from termination to ECM block...

I'll clean all the blocks with Carbon.tet and check each wire...Tomorrow...

Thank you Ron...

#7

I checked continuity between the 6 injector grounds and all check good...

Positive leads are hot with key on...

I can manually trigger each injector from the battery and it adds fuel to that cylinder and fires it as if it wants to crank...

Only thing left is that the ECM is bad???

Any tests I can do for the injector ground trigguring inside the ECM?

Positive leads are hot with key on...

I can manually trigger each injector from the battery and it adds fuel to that cylinder and fires it as if it wants to crank...

Only thing left is that the ECM is bad???

Any tests I can do for the injector ground trigguring inside the ECM?

Last edited by Steve1234; 06-21-2018 at 01:06 PM.

#8

#10

#11

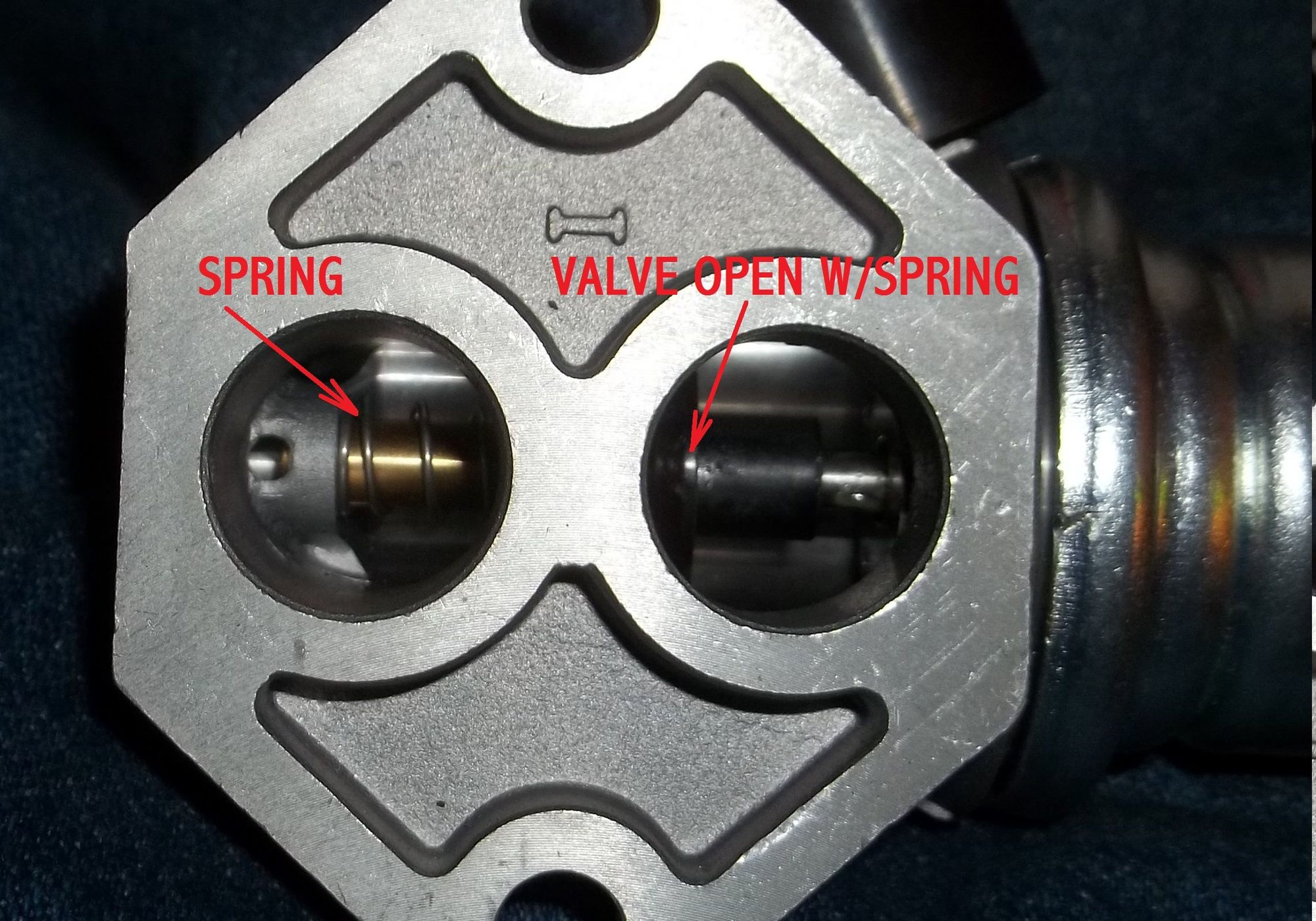

IAC valve is stuck open...

I took a slice of card paper and closed up the air passages and left a small portion of the 2 holes un-covered and reattached the IAC Temporarily

to check for vacuum leaks...Trans Modulator hose was off below so I plugged it off temporarily...

Vacuum line to the reservoir tank and heater/AC controls has a vacuum leak under dash...Another day...

So far with those blocked off it idles smoother 500-600 rpm...

Still need a trusty timing light to get the distributor in time...It's close though...

Radiator fan has a crack at the base and the fan clutch free wheels...

Going to go ahead and replace the IAC and the IAT also...

Don't know why I couldn't get the noid light to hit on the injector connectors unless it was a faulty connection at the junction blocks and after un-pluging and pluging in many times it finally made contact...I'll put some dielectric grease on the pins tomorrow...

Alt. charging at 13.6V Good to go...

Pulled the bed to check the pump...

Previous owner broke the catches off the pump harness connector...I found one on EBAY

Over the hump now...Thanks again Ron...

I took a slice of card paper and closed up the air passages and left a small portion of the 2 holes un-covered and reattached the IAC Temporarily

to check for vacuum leaks...Trans Modulator hose was off below so I plugged it off temporarily...

Vacuum line to the reservoir tank and heater/AC controls has a vacuum leak under dash...Another day...

So far with those blocked off it idles smoother 500-600 rpm...

Still need a trusty timing light to get the distributor in time...It's close though...

Radiator fan has a crack at the base and the fan clutch free wheels...

Going to go ahead and replace the IAC and the IAT also...

Don't know why I couldn't get the noid light to hit on the injector connectors unless it was a faulty connection at the junction blocks and after un-pluging and pluging in many times it finally made contact...I'll put some dielectric grease on the pins tomorrow...

Alt. charging at 13.6V Good to go...

Pulled the bed to check the pump...

Previous owner broke the catches off the pump harness connector...I found one on EBAY

Over the hump now...Thanks again Ron...

#13

Well...I still have a problem!

New IAT and IAC...Hot 12 volts to the red wire of the IAC but not idling down...I hear no vacuum leaks other than the IAC vent..

Wires to the IAC check out with continuity...

Only thing I can think of is a vacuum leak between the upper and lower manifold...I pulled each vacuum line off and plugged up each of the vacuum nipples but no change...

The new IAC valve stays open when off the intake un-plugged...Does the IAC solenoid pull the valve open when it works right or does it push closed when ECM activates it???

What sensors operate the IAC? Only thing I haven't replaced is the MAF sensor...

New IAT and IAC...Hot 12 volts to the red wire of the IAC but not idling down...I hear no vacuum leaks other than the IAC vent..

Wires to the IAC check out with continuity...

Only thing I can think of is a vacuum leak between the upper and lower manifold...I pulled each vacuum line off and plugged up each of the vacuum nipples but no change...

The new IAC valve stays open when off the intake un-plugged...Does the IAC solenoid pull the valve open when it works right or does it push closed when ECM activates it???

What sensors operate the IAC? Only thing I haven't replaced is the MAF sensor...

#14

IAC valve is a solenoid, so has a spring inside that pushes it closed when there is no power.

Key on, engine off, should have IAC Valve open all the way

Unplugs its wires and it should close all the way, repeat as need to make sure it works

Computer Pulses the Ground to raise and lower voltage at IAC Valve to hold it open against spring pressure.

Extremely accurate system, holds idle RPMs, +/- 3 RPMs from "Target" idle in memory

Target idle is based on temperature of coolant/engine, above 170degF Base target idle is set, manual trans about 650, automatic 750

Your new IAC Valve is bad

If you unplug IAC Valve on warmed up engine RPMs should drop to 500 or engine should stall either is correct

Key on, engine off, should have IAC Valve open all the way

Unplugs its wires and it should close all the way, repeat as need to make sure it works

Computer Pulses the Ground to raise and lower voltage at IAC Valve to hold it open against spring pressure.

Extremely accurate system, holds idle RPMs, +/- 3 RPMs from "Target" idle in memory

Target idle is based on temperature of coolant/engine, above 170degF Base target idle is set, manual trans about 650, automatic 750

Your new IAC Valve is bad

If you unplug IAC Valve on warmed up engine RPMs should drop to 500 or engine should stall either is correct

#15

#16

Well...When I bought the Ranger and disassembled the engine The IAC valve had the solenoid facing towards the firewall...

I stopped by our local U-Pullit to pick up a Motorcraft IAC...

The engine I removed it from had the solenoid facing forward...WHAT?

When I got home I put it on with the solenoid facing forward...

Everything is working great now...

My mistake...

I stopped by our local U-Pullit to pick up a Motorcraft IAC...

The engine I removed it from had the solenoid facing forward...WHAT?

When I got home I put it on with the solenoid facing forward...

Everything is working great now...

My mistake...

#17

Good work.

Not sure what engine would use "normally open" IAC valve, you would get run away idle RPMs which could cause safety issue with automatics in gear.

Air flow direction might cause IAC valve to be pulled full open, although never tested that before, i.e. the mounting direction of IAC Valve on upper intake

Not sure what engine would use "normally open" IAC valve, you would get run away idle RPMs which could cause safety issue with automatics in gear.

Air flow direction might cause IAC valve to be pulled full open, although never tested that before, i.e. the mounting direction of IAC Valve on upper intake

Thread

Thread Starter

Forum

Replies

Last Post