Sudden hard stumbling at idle with throbbing acceleration

#1

Sudden hard stumbling at idle with throbbing acceleration

Hi guys, I'm new to the forum here. So I hope I am posting this in the right thread.

I have a 1998 Ford Ranger XLT 2.5L 4 cylinder. It is a manual.

I went to start it in the morning and it suddenly had a terrible idle that rocks the car everywhere and almost cuts the engine. After about a couple minutes of idling, it will sometimes smooth out at idle. But when you go to push the gas, there is no power behind it and if you hold the accelerator down, the engine will rev up for a short moment and then drop out over and over again until you release the pedal.

The problem is bad enough you cant even accelerate the car on the street.

I had codes for a bad IAC valve that I put off for a few months, as well as a pending code for bank1 sensor b1 O2 sensor. I figured those might be the problem and replaced both, but it fixed nothing.

I have noticed that if I unplug the new IAC valve that the idle gets better, but it doesn't fix the acceleration problem. I also noticed that if I unplug the MAF sensor everything fixes itself and the car is driveable but the engine gets really hot.

Is this a maf problem or something else? Anyone have an idea, or had the same problem before?

Thanks!

I have a 1998 Ford Ranger XLT 2.5L 4 cylinder. It is a manual.

I went to start it in the morning and it suddenly had a terrible idle that rocks the car everywhere and almost cuts the engine. After about a couple minutes of idling, it will sometimes smooth out at idle. But when you go to push the gas, there is no power behind it and if you hold the accelerator down, the engine will rev up for a short moment and then drop out over and over again until you release the pedal.

The problem is bad enough you cant even accelerate the car on the street.

I had codes for a bad IAC valve that I put off for a few months, as well as a pending code for bank1 sensor b1 O2 sensor. I figured those might be the problem and replaced both, but it fixed nothing.

I have noticed that if I unplug the new IAC valve that the idle gets better, but it doesn't fix the acceleration problem. I also noticed that if I unplug the MAF sensor everything fixes itself and the car is driveable but the engine gets really hot.

Is this a maf problem or something else? Anyone have an idea, or had the same problem before?

Thanks!

#2

Welcome to the forum

What were the exact codes, Ford code list here: https://therangerstation.com/tech_li...II_codes.shtml

Each sensor has several codes the computer can pick from, so the exact code is good but looking at ALL the codes for that sensor the computer DID NOT use is helpful as well

Googling a code number is OK, but doesn't give you the FULL PICTURE

What brand of IAC Valve did you get?

There have been many posts about 3rd part IAC Valves not fixing a problem and in some cases making it worse

You really need to use a Motorcraft IAC Valve, even if its from a wrecking yard

Pull off the IAC Valve and plug it back in, or plug in the old one first

Turn the key on

Look inside the valve and unplug the wires, valve should have been open all the way and it should now close, only moves 3/8" but you can see it move

Repeat plugging it in and unplugging it until you are satisfied it is moving

IAC valve is important for cold start since a cold engine needs to run at higher idle, and thats what IAC Valve is there for to set idle RPMs

With key on the computer sends the IAC valve 12volts, so it opens all the way for start up, this is why any EFI engine should REV to 1,500rpm when it starts and should then drop down as computer reduces voltage to IAC Valve, no REV at start up, cold or warm, can mean IAC Valve issue

ECT(engine coolant temp) sensor, this is ONLY USED by the computer, it is a 5volt sensor that tells the computer if it needs to "choke" the engine if its cold, or if this is a warm restart, you can test these but not expensive to replace when having a cold start issue

Cold engines still need to be "choked" or they will run poorly if at all until they warm up a bit, ECT sensor causes "choke" to be set

The dash board temp gauge uses a 12volt ECT SENDER, just FYI, so not interchangeable

Unplugging the MAF sensor tells the computer to run in "safe" mode, richer fuel mix, its running off pre-programmed tables for air/fuel mix, it ignores all other sensors except RPM and throttle position

So unplugging the MAF can "get you home" but doesn't really tell you much about what might be wrong.

Cleaning the MAF is easy and should be done once a year, for sure every 2 years

The MAF sensor and throttle sensor are compared by the computer, your computer "knows" its running a 2.5 liter engine, so it "knows" exactly how much air should be coming in at ANY RPM, its just math

So if the MAF sensor is showing out of range data when compared to RPM and throttle position it will set a code to check MAF or Throttle sensors, because one is not matching the other

The MAF sensors main purpose is to tell computer the WEIGHT of the incoming air, colder air is heavier so needs more fuel added, lighter air, say at 4,000ft elevation, needs less fuel added

MAF = Mass air flow, Mass is weight

What were the exact codes, Ford code list here: https://therangerstation.com/tech_li...II_codes.shtml

Each sensor has several codes the computer can pick from, so the exact code is good but looking at ALL the codes for that sensor the computer DID NOT use is helpful as well

Googling a code number is OK, but doesn't give you the FULL PICTURE

What brand of IAC Valve did you get?

There have been many posts about 3rd part IAC Valves not fixing a problem and in some cases making it worse

You really need to use a Motorcraft IAC Valve, even if its from a wrecking yard

Pull off the IAC Valve and plug it back in, or plug in the old one first

Turn the key on

Look inside the valve and unplug the wires, valve should have been open all the way and it should now close, only moves 3/8" but you can see it move

Repeat plugging it in and unplugging it until you are satisfied it is moving

IAC valve is important for cold start since a cold engine needs to run at higher idle, and thats what IAC Valve is there for to set idle RPMs

With key on the computer sends the IAC valve 12volts, so it opens all the way for start up, this is why any EFI engine should REV to 1,500rpm when it starts and should then drop down as computer reduces voltage to IAC Valve, no REV at start up, cold or warm, can mean IAC Valve issue

ECT(engine coolant temp) sensor, this is ONLY USED by the computer, it is a 5volt sensor that tells the computer if it needs to "choke" the engine if its cold, or if this is a warm restart, you can test these but not expensive to replace when having a cold start issue

Cold engines still need to be "choked" or they will run poorly if at all until they warm up a bit, ECT sensor causes "choke" to be set

The dash board temp gauge uses a 12volt ECT SENDER, just FYI, so not interchangeable

Unplugging the MAF sensor tells the computer to run in "safe" mode, richer fuel mix, its running off pre-programmed tables for air/fuel mix, it ignores all other sensors except RPM and throttle position

So unplugging the MAF can "get you home" but doesn't really tell you much about what might be wrong.

Cleaning the MAF is easy and should be done once a year, for sure every 2 years

The MAF sensor and throttle sensor are compared by the computer, your computer "knows" its running a 2.5 liter engine, so it "knows" exactly how much air should be coming in at ANY RPM, its just math

So if the MAF sensor is showing out of range data when compared to RPM and throttle position it will set a code to check MAF or Throttle sensors, because one is not matching the other

The MAF sensors main purpose is to tell computer the WEIGHT of the incoming air, colder air is heavier so needs more fuel added, lighter air, say at 4,000ft elevation, needs less fuel added

MAF = Mass air flow, Mass is weight

Last edited by RonD; 09-20-2019 at 10:41 AM.

#3

Thanks for the quick response

Both codes were p0113 & p0135. Thanks for the code list, that will be handy in the future. The codes that were thrown were the same codes I had had for a while, so that's why I am kind of stumped now.

I had to buy an IAC in a hurry so I bought one from a local auto zone, duralast brand. I will try pulling it off and doing what you said to see if it is truly operational.

I also cleaned my maf as well. No change. I thought about the tps possibly being bad, but figured if it still ran after unplugging the maf then it probably wasn't it.

The only things I can think of from other online research were pcv vacuum line or fuel issue. But again not sure if it would be fuel if it runs fine in the limp mode when unplugging the maf.

Hope that gives you a little more info.

I had to buy an IAC in a hurry so I bought one from a local auto zone, duralast brand. I will try pulling it off and doing what you said to see if it is truly operational.

I also cleaned my maf as well. No change. I thought about the tps possibly being bad, but figured if it still ran after unplugging the maf then it probably wasn't it.

The only things I can think of from other online research were pcv vacuum line or fuel issue. But again not sure if it would be fuel if it runs fine in the limp mode when unplugging the maf.

Hope that gives you a little more info.

#4

P0135 02 Sensor Heater Circuit Malfunction (Bank 1 Sensor 1)

Heater in an O2 sensor gets it up to above 650degF faster so computer can use it sooner, O2 don't work under 600degF

In 1998 heater power should come from fuse #13 in engine bay, but not sure on the 2.5l, it also powers EVAP canister

Or it could be a damaged wire for the heater, the computer is the Ground for the heater so if it doesn't "see" 12volts on that wire passing thru the heater it will set that code

P0113 Intake Air Temperature Circuit High Input

IAT sensor should be on the upper intake, 2 wire sensor, but it can also be on the air filter box, it is used in conjunction with the MAF sensor and ECT sensor to set correct air/fuel mix

It is sent 5volts from the computer, almost all sensors share this 5volts, it gets back a lower voltage and that indicates the "air temp", the lower the voltage the warmer the air, so "circuit high" would indicate a voltage close to 5volts coming back from this sensor, which couldn't happen unless it was -200degF outside, lol

Bad sensor or a short between the two wires

Neither of these should cause running issues maybe the O2 heater and blown fuse, but the computer would just ignore the IAT sensor until it was repaired

The TPS can be tested with volt or ohm meter its a pretty simple device, same as a volume control or light dimmer

It gets 5volts and sends back under 1 volt, .6-.99v when throttle is closed, above 4.5v when throttle is wide open

Center wire is the one to test, key on it should show under 1 volt, open throttle and voltage should go up steadily, no jump or drop, until it gets to 4.5v or higher

You can use a sew needle to pierce wires for testing

TPS failing will usually show up as a "dead spot" on gas pedal position, voltage to computer drops suddenly so computer thinks you took your foot off the gas pedal suddenly

Heater in an O2 sensor gets it up to above 650degF faster so computer can use it sooner, O2 don't work under 600degF

In 1998 heater power should come from fuse #13 in engine bay, but not sure on the 2.5l, it also powers EVAP canister

Or it could be a damaged wire for the heater, the computer is the Ground for the heater so if it doesn't "see" 12volts on that wire passing thru the heater it will set that code

P0113 Intake Air Temperature Circuit High Input

IAT sensor should be on the upper intake, 2 wire sensor, but it can also be on the air filter box, it is used in conjunction with the MAF sensor and ECT sensor to set correct air/fuel mix

It is sent 5volts from the computer, almost all sensors share this 5volts, it gets back a lower voltage and that indicates the "air temp", the lower the voltage the warmer the air, so "circuit high" would indicate a voltage close to 5volts coming back from this sensor, which couldn't happen unless it was -200degF outside, lol

Bad sensor or a short between the two wires

Neither of these should cause running issues maybe the O2 heater and blown fuse, but the computer would just ignore the IAT sensor until it was repaired

The TPS can be tested with volt or ohm meter its a pretty simple device, same as a volume control or light dimmer

It gets 5volts and sends back under 1 volt, .6-.99v when throttle is closed, above 4.5v when throttle is wide open

Center wire is the one to test, key on it should show under 1 volt, open throttle and voltage should go up steadily, no jump or drop, until it gets to 4.5v or higher

You can use a sew needle to pierce wires for testing

TPS failing will usually show up as a "dead spot" on gas pedal position, voltage to computer drops suddenly so computer thinks you took your foot off the gas pedal suddenly

#8

The last code means computer can't close IAC Valve enough to lower RPMs to its "target" idle, so either IAC valve is not responding or you have a vacuum leak

After engine is fully warmed up and idling, unplug IAC Valve and RPMs should drop to 500 or so, maybe engine will stall, either is GOOD, it means no vacuum leaks

The TID stuff is useless to me unless I wanted to look them up, I don't, lol, if you want to post the definitions or the TID codes thats fine

Fuel trims need to be defined with engine operating temp, +42 is fine if engine is cold

So fuel trims are really on helpful after engine is fully warmed up

O2 bank 1 sensor 1 is the O2 sensor closest to the engine, its the one the computer uses to adjust air/fuel mix on the fly

O2 bank 1 sensor 2 is the one after the Cat converter it is used to test if Cat is working and also to adjust long term fuel trims

STFT short term fuel trims are calculated on the fly and thats 0 STFT

After this mix is burned in the engine the O2 sensor(B1S1) tells computer if burn was lean or rich, if lean computer changes STFT to +2(2%) then sees if O2 likes that, if not then +4, +6 +7, ect...............until O2 shows good burn

If it was Rich burn then same thing only -2, -4, ect................

All this happens in a few seconds so engine is never running lean or rich

The + and - are actually fuel injector open times, if computer calculated it needs to open injectors 100milliseconds but that shows lean then it opens injectors 102ms then 104ms, ect.....thats the 2% or 9%

Between -10 and +10 is fairly normal for most vehicle as they get older nothing wrong , MPG should be the same

You will get lean or rich codes when it -20 or +20 for any length of time

After engine is fully warmed up and idling, unplug IAC Valve and RPMs should drop to 500 or so, maybe engine will stall, either is GOOD, it means no vacuum leaks

The TID stuff is useless to me unless I wanted to look them up, I don't, lol, if you want to post the definitions or the TID codes thats fine

Fuel trims need to be defined with engine operating temp, +42 is fine if engine is cold

So fuel trims are really on helpful after engine is fully warmed up

O2 bank 1 sensor 1 is the O2 sensor closest to the engine, its the one the computer uses to adjust air/fuel mix on the fly

O2 bank 1 sensor 2 is the one after the Cat converter it is used to test if Cat is working and also to adjust long term fuel trims

STFT short term fuel trims are calculated on the fly and thats 0 STFT

After this mix is burned in the engine the O2 sensor(B1S1) tells computer if burn was lean or rich, if lean computer changes STFT to +2(2%) then sees if O2 likes that, if not then +4, +6 +7, ect...............until O2 shows good burn

If it was Rich burn then same thing only -2, -4, ect................

All this happens in a few seconds so engine is never running lean or rich

The + and - are actually fuel injector open times, if computer calculated it needs to open injectors 100milliseconds but that shows lean then it opens injectors 102ms then 104ms, ect.....thats the 2% or 9%

Between -10 and +10 is fairly normal for most vehicle as they get older nothing wrong , MPG should be the same

You will get lean or rich codes when it -20 or +20 for any length of time

#9

Unplugged iac at idle

Unfortunately the fuse looked good. That would have been an easy fix none the less.

I did what you suggested with the IAC. The first time I unplugged it it caused it to stumble a little harder, then after plugging it back in it stumbled less. The 2nd time I did it, it didn't effect anything. I also pulled the PCV valve. It had some oil on it (looked original). It rattled fine, but i will probably end up replacing it and the hose anyway. The hose looks like a pain to get to though.

I also tried looking for vacuum leaks by tracking down hoses and feeling around on them. Didn't come up with anything yet. I ran out of time tonight, so I will test the tps sensor tomorrow.

Something strange though, I unplugged the sensor that is next to the IAC valve. I assume it is an EGR sensor. After I unplugged it and plugged it back in, the car accelerated normally for about a minute, until I backed it out of the driveway to drive it and it went back to stumbling again and could barely make it back up the driveway. Would a bad egr sensor cause that much problem?

Thanks for all the help and info already.

I did what you suggested with the IAC. The first time I unplugged it it caused it to stumble a little harder, then after plugging it back in it stumbled less. The 2nd time I did it, it didn't effect anything. I also pulled the PCV valve. It had some oil on it (looked original). It rattled fine, but i will probably end up replacing it and the hose anyway. The hose looks like a pain to get to though.

I also tried looking for vacuum leaks by tracking down hoses and feeling around on them. Didn't come up with anything yet. I ran out of time tonight, so I will test the tps sensor tomorrow.

Something strange though, I unplugged the sensor that is next to the IAC valve. I assume it is an EGR sensor. After I unplugged it and plugged it back in, the car accelerated normally for about a minute, until I backed it out of the driveway to drive it and it went back to stumbling again and could barely make it back up the driveway. Would a bad egr sensor cause that much problem?

Thanks for all the help and info already.

Last edited by 98rangerxlt2.5L4cyl; 09-20-2019 at 09:19 PM.

#10

A leaking EGR valve could, or the EGR solenoid, but not the EGR sensor

Locate the EGR valve, it has a vacuum line, follow that line to the EGR Solenoid, it has 2 vacuum lines, unplug the one you just followed

Start engine

Put your finger over the PORT on the solenoid that is now unplugged, should be NO vacuum sucking in on your finger, if there is then its leaking and needs to be replaced, but engine should be running better now with that hose unplugged

Locate the EGR valve, it has a vacuum line, follow that line to the EGR Solenoid, it has 2 vacuum lines, unplug the one you just followed

Start engine

Put your finger over the PORT on the solenoid that is now unplugged, should be NO vacuum sucking in on your finger, if there is then its leaking and needs to be replaced, but engine should be running better now with that hose unplugged

#11

Update

Alright, here is an update.

Things I have replaced:

Iac Valve,

Throttle position sensor,

Spark plugs,

Spark plug wires,

PCV valve,

Pcv hose,

Throttle body gasket,

Upper manifold gasket,

Lower manifold gasket,

Dpfe hoses,

Dpfe sensor,

Egr valve,

Front O2 sensor,

Air filter,

Fuel injector o-rings,

Cleaned fuel injectors and rail,

Cleaned valves,

Cleaned air intake manifold,

Cleaned throttle body,

Cleaned maf sensor,

Cleaned air temp sensor,

A lot of this stuff needed to be replaced, so most wasnt wasted.

But, I still have the same issue. I was so sure it was a vacuum leak.

Terrible idle at start, car thrashes and sometimes dies. After a warm up, idle gets better but acceleration is always terrible. While holding down the throttle it will continually drop out over and over again with no acceleration. And when I pull the maf sensor and put the car in limp mode the engine and acceleration run perfectly normal.

I'm at a loss.

Things I have replaced:

Iac Valve,

Throttle position sensor,

Spark plugs,

Spark plug wires,

PCV valve,

Pcv hose,

Throttle body gasket,

Upper manifold gasket,

Lower manifold gasket,

Dpfe hoses,

Dpfe sensor,

Egr valve,

Front O2 sensor,

Air filter,

Fuel injector o-rings,

Cleaned fuel injectors and rail,

Cleaned valves,

Cleaned air intake manifold,

Cleaned throttle body,

Cleaned maf sensor,

Cleaned air temp sensor,

A lot of this stuff needed to be replaced, so most wasnt wasted.

But, I still have the same issue. I was so sure it was a vacuum leak.

Terrible idle at start, car thrashes and sometimes dies. After a warm up, idle gets better but acceleration is always terrible. While holding down the throttle it will continually drop out over and over again with no acceleration. And when I pull the maf sensor and put the car in limp mode the engine and acceleration run perfectly normal.

I'm at a loss.

#15

#16

Strange

Alright, so I went out this evening to check the maf with a multimeter. I had good voltage. Couldn't really get a good reading on anything else. But the strange part is that after checking it, I started it up to see if I could get a reading on the return wire to the ecm, and the car was suddenly running smoothly. I made sure the maf was plugged in, and it was. I turned the car off, and back on 4 times and it idled and accelerated great each time. Took it for a 5 minute ride and everything seemed great. I wonder if something was going wrong at the connector. Or if the ecm just reset itself after a few startups and the problem was already fixed in the list of things I maintenanced. There was a very very slight hiccup in the idle but nothing terrible.

Hoping it stays that way. Hesitant to take it to work just yet. Will try to get another graph on it tomorrow, with it running well.

Hoping it stays that way. Hesitant to take it to work just yet. Will try to get another graph on it tomorrow, with it running well.

#17

No avail

Well, back again. Started it this evening and it was right back to where we started. Idle still smooths out after warmup, assuming that is because of the o2 sensor coming on. I will be changing the fuel filter in the morning since it's cheap, but doubt that will transform anything at this point.

#18

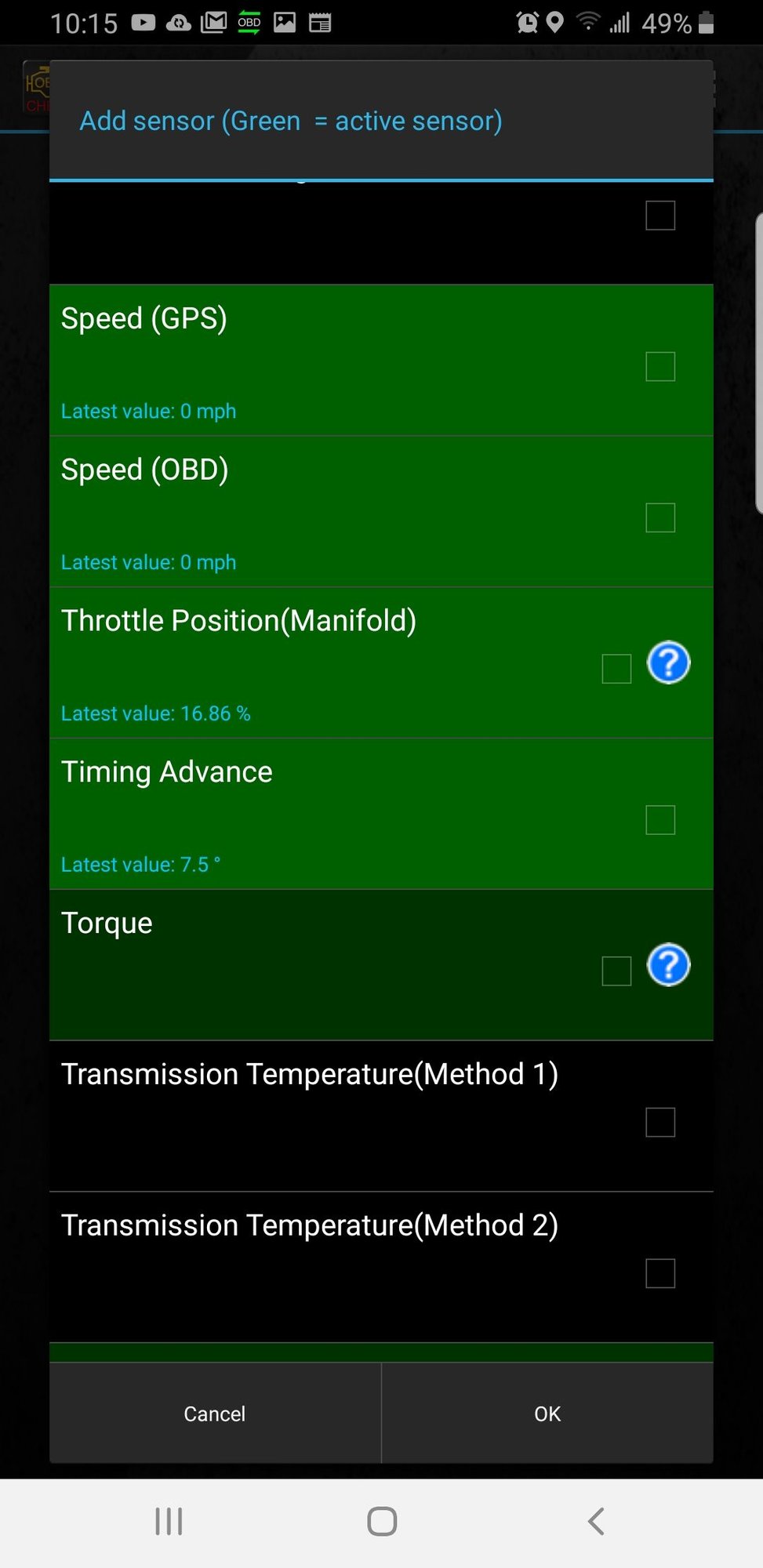

Looking at the graphs posted, looks like the MAF pattern is not rising up along with the TPS pattern. Don't see a voltage chart on your screen shot but a normal MAF reading at idle ( approx. 600 rpm ) should be around 0.60 volts and climb to about 3.9 volts near 5000 rpm. It should rise along with RPM increase with no dropouts which your screen capture does show. If you are not releasing throttle during your test, then either the MAF or the wiring is suspect. That is assuming there are no airflow restrictions through the exhaust or on the intake side such as air intake duct. You can rule those out by just removing the lid of the air filter housing with the MAF still attached of course, and on the exhaust side, remove the upstream o2 sensor, leaving it plugged into connector so it won't set an electrical fault code. This should allow any restrictions to be bypassed to help pinpoint your problem. Hope this helps. Louis N.

Thread

Thread Starter

Forum

Replies

Last Post

Danec71

General Technical & Electrical

41

07-13-2024 04:17 PM